NEW VersaSTUDIO BY-20 Desktop Direct-to-Film Printer

-

BY-20

MSRP

$8,495 US*

Limited time only

Get Promo

SAVE $995

When Bundle with Vastex PTF-COMBO-100* Promotion valid through 12/31/2025. See promo page for terms and conditions.

The all-new VersaSTUDIO BY-20 is the ultimate desktop direct-to-film printer…and more. Simple to use, reliable and efficient, the BY-20 makes decorating apparel and accessories with vibrant, detailed graphics quick and easy – even for those with no prior printing experience. Plus, with the BY-20’s integrated contour-cutting functionality, you can also produce heat transfer graphics from PVC sheets – all with a single, affordable compact device.

- Easy-to-use, compact, affordable DTF printer for those who want to start an apparel business, or for existing DTF users seeking to expand their current product offerings

- Prints vibrant, detailed DTF graphics that can be transferred to a wide variety of fabrics with no weeding required

- The only desktop DTF printer with sheet cut and contour-cutting capabilities – can also be used for traditional print and cut applications

- Optimized print modes for improved productivity

- Integrates with popular DTF powder shaker and heater units for an automated system

Create Customized Apparel & Accessories with

One Compact, Easy-to-Use Device

The VersaSTUDIO BY-20 is a highly versatile desktop device

ideal for a range of direct-to-film apparel applications, such as creating

custom T-shirts, sportswear, tote bags, and more. You can also use the BY-20’s

integrated contour cutting capabilities to produce jersey numbers and other

heat transfer graphics.

Here are some examples:

Create eye-catching custom T-shirts quickly and easily. With the BY-20 direct-to-film system, you can add complex graphics and text with no weeding or masking required.

With the BY-20 direct-to-film system, enhancing a wide variety of sports apparel with vibrant, detailed graphics is a breeze, even for print novices.

The BY-20 direct-to-film system makes customizing or personalizing aprons, chef clothing, and other types of kitchen clothing easier than ever.

Add value and appeal to any tote bag easily and cost effectively. The BY-20 allows even those with little or no direct-to-film graphics experience to customize like a pro.

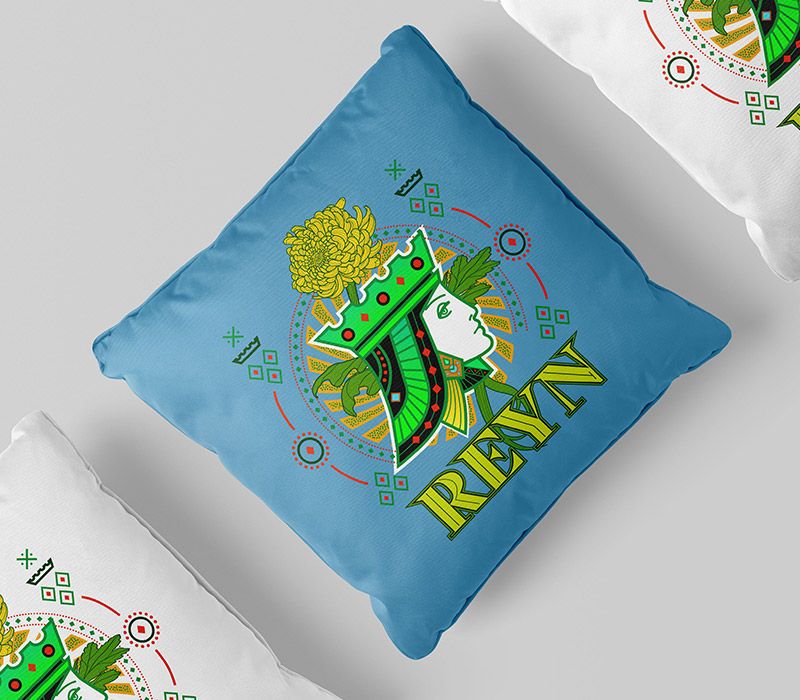

Decorate pillow covers and other home décor items with stunning graphics that add stylistic touches to any interior setting. With the BY-20 it only requires a few simple steps.

The BY-20 direct-to-film system makes customizing team jerseys with colorful logos and designs a simple process. You can also use the BY-20’s cutting capabilities to create heat transfer numbers.

The Key to Your DTF Workflow

Learn how to print direct-to-film graphics, from design to output in one seamless workflow, using the Roland DG BY-20 printer/cutter and FlexiDESIGNER VersaSTUDIO Edition.

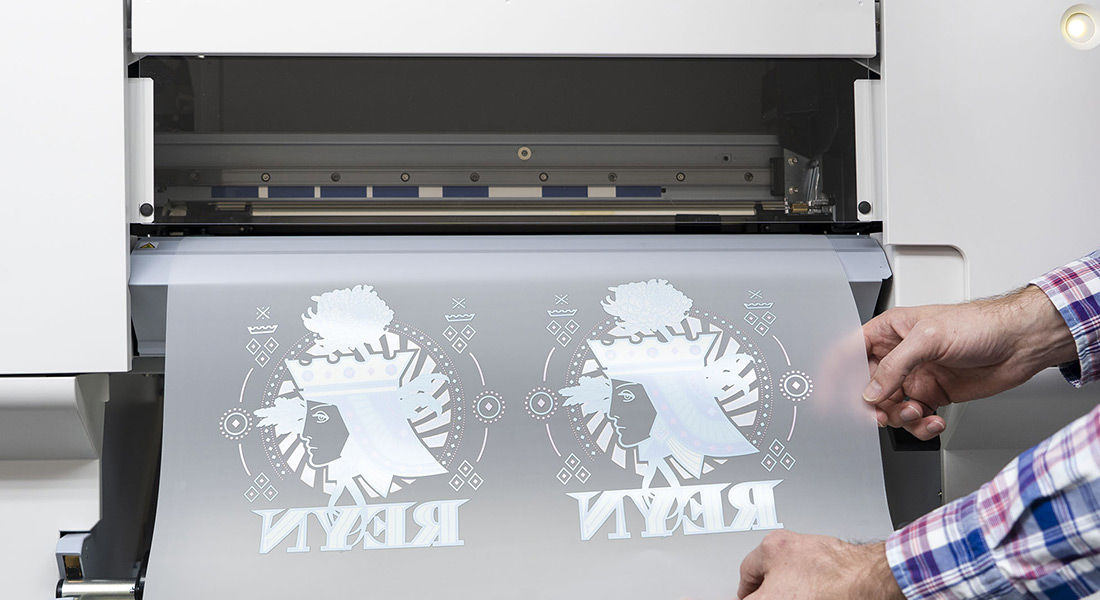

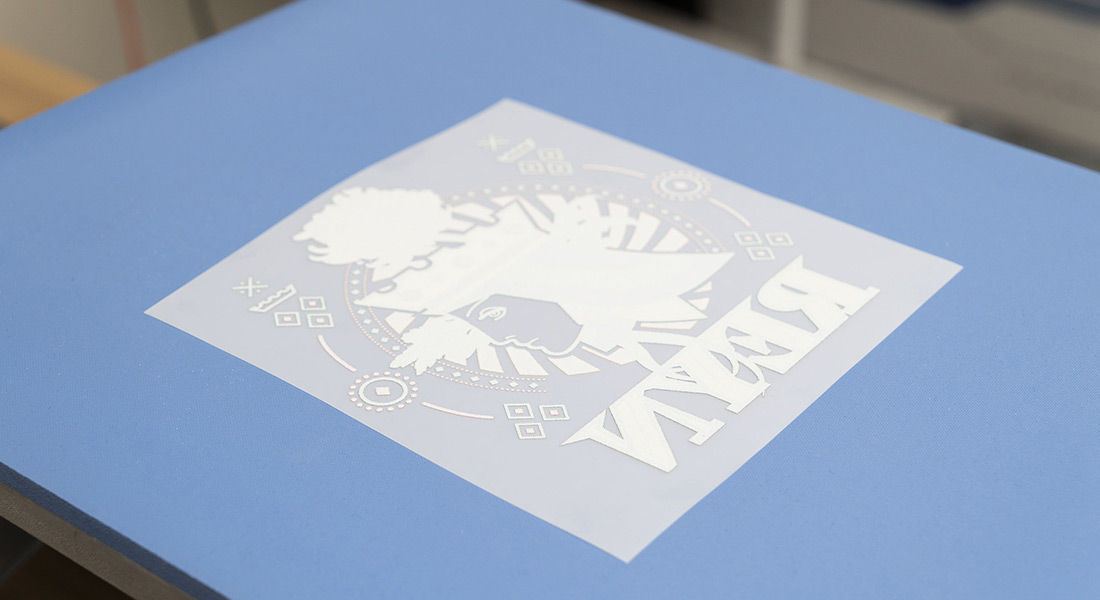

Direct-to-Film in Four Easy Steps

The BY-20 direct-to-film workflow is a quick and easy four-step process, with no weeding or masking required. Roland DGA offers the printer, transfer film, powder, and inks (each sold separately) for a complete solution. Plus, the system integrates with popular DTF powder shaker and heater units for an automated system.

Improves the Design and Efficiency of Apparel Decoration

With its user-friendly operation, fast print speeds, and intuitive software, the BY-20 direct-to-film system makes designing and creating customized apparel easier than ever. You can also transfer your BY-20-produced graphics to a wide variety of materials, including cotton, polyester, denim, nylon, rayon, and more.

Easy to Use, Even for Beginners

The BY-20 is so easy to use, even beginners can produce professional-quality output. After pressing the power button, all other operations – from printer setup and maintenance to sheet cutting – can be performed with the intuitive utility software. There’s even a support function that guides you through the various menu operations in an easy-to-understand manner.

Professional Quality

The BY-20 consistently delivers quality results that professionals can rely on. That’s because it features the same advanced print technologies as Roland DG’s state-of-the-art wide-format printers. You can expect rich, colorful, high-definition output, print after print. Plus, the included design and output software provides all the features and tools you need to create stunning graphic quickly and easily.

Efficient Production

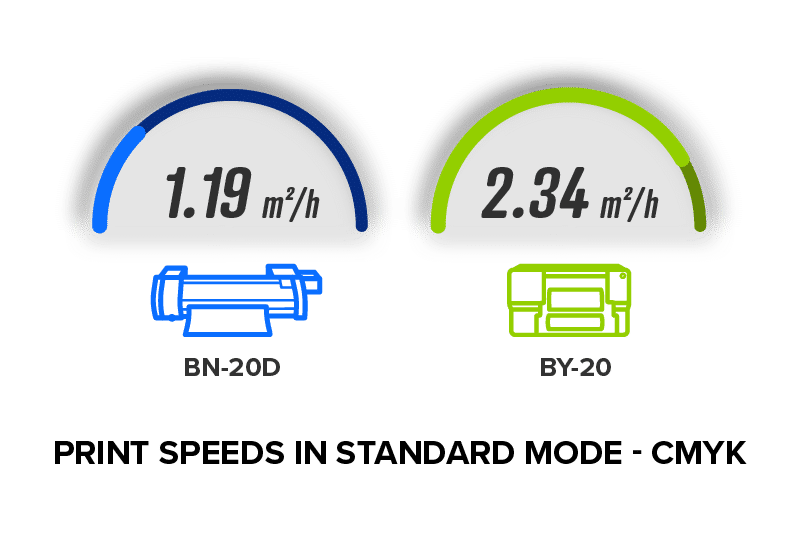

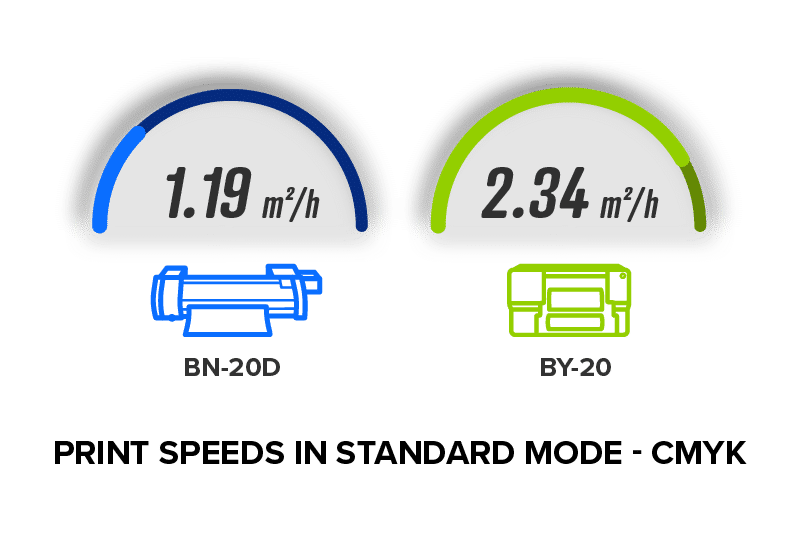

Featuring print speeds twice as fast as previous models, the BY-20 offers an ideal workflow for DTF. You’ll be able to turn around jobs cost effectively and in a timely manner. A host of convenient user features, including front-loading media and ink systems, simplify workflow for maximum efficiency. Plus, the BY-20’s easy integration with popular DTF powder shaker and heater units allows for an automated system.

A Direct-to-Film Printer Tailor Made for You and Your Business

Included FlexiDESIGNER VersaSTUDIO Edition Software

The BY-20’s included FlexiDESIGNER VersaSTUDIO Edition design and output software allows even those with little or no printing experience to consistently produce high-quality graphics. This feature-filled, intuitive software offers a host of tools for creating shapes, text, and effects, while also simplifying the print and cut workflow.

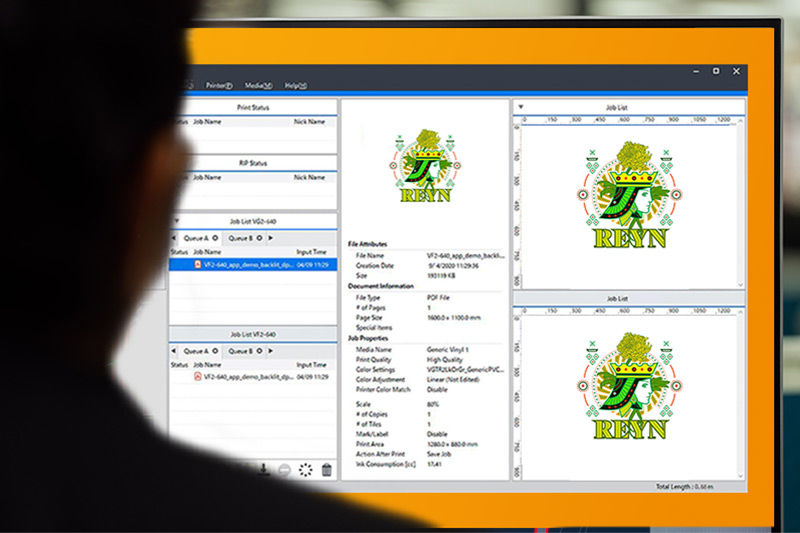

Included VersaWorks 6 Output Software

For users looking for even greater control over output settings and capabilities, every BY-20 printer comes with powerful, simple-to-use VersaWorks 6 output software. VersaWorks 6 includes useful features that optimize quality and streamline processes for the printer, ink, and media. It also simplifies the setup of print layouts, generates cut lines for print and cut applications, and provides built-in color management tools that make reproducing specific colors quick and easy.

Roland DG Connect App For Everything Creative

Gain a detailed understanding of your entire print operation while keeping your device running at optimum performance with a user-friendly app specially designed to integrate seamlessly with your VersaSTUDIO BY-20. Reduce downtime and improve efficiency with a machine monitoring assistant that works in complete harmony with your device.

Additional Features

Built-in functionality highly automates the media setup process, preparing the printer for varying material types and thicknesses, facilitating media loading, minimizing waste to reduce costs, and more.

BY-20 inks and powders are Oeko-Tex® ECO PASSPORT certified, guaranteeing the safety of textile products produced and providing assurance they do not contain harmful levels of toxic substances.

Provides intuitive and quick access to the items you want to use and comfortably supports operation from printer setup to maintenance and sheet cutting.

The BY-20 direct-to-film printer can be easily integrated with popular shaker and heater units, for an automated DTF system.

LED lights indicate the printer’s status – such as “operating,” “temporarily on standby,” or “in error.” Even from a distance, the varying colors provide an update at a glance.

The BY-20 is ethernet compatible. Print data can be sent and maintenance instructions can be given, even from remote locations within the same network.

Produce and Profit

The BY-20 desktop direct-to-film system lets you increase the value and appeal of T-shirts, hoodies, bags, and many other popular and profitable items by adding vibrant, customized graphics.

Numbers shown are estimates based on averages only and will vary by each job and use.

Expand Your Creative Possibilities

Roland DG’s Industry-Leading Warranty and Support

Every BY-20 also comes with Roland DG’s industry-best customer service and support as well as a One-Year Trouble-Free Warranty. Your success is our success, so you can rest assured we’ll be with you every step of the way to make sure you are fully satisfied with the performance of your Roland DG device.

Additional Information

Request a Reseller

Datasheet

Download Your BY-20 Series Datasheet

Get your digital guide to all the features, applications, benefits and specifications of the Direct-to-Film Printer.

Download DatasheetSpecifications

| BY-20 | |||

|---|---|---|---|

| Printing Method | Piezo ink-jet method | ||

| Media | Width | 5.91 to 20.2 in. (150 to 515 mm) | |

| Thickness | Maximum 39.3 mil (1.0 mm) with liner, for printing Maximum 15.7 mil (0.4 mm) with liner and 8.6 mil (0.22 mm) without liner, for cutting |

||

| Roll outer diameter | Maximum 5.9 in. (150 mm) | ||

| Roll weight | Maximum 13.2 lb. (6 kg) | ||

| Core diameter | 3 in. (76.2 mm) or 2 in. (50.8 mm) | ||

| Printing/cutting width (*1) | Maximum 18.89 in. (480 mm) | ||

| Ink | Type | 220-ml cartridge | |

| Colors | Cyan, Magenta, Yellow, Black, White | ||

| Printing resolution (dots per inch) | Maximum 1,440 dpi | ||

| Cutting speed | 0.39 to 5.9 in/s (10 to 150 mm/s) | ||

| Blade force (*2) | 30 to 500 gf | ||

| Blade | Type | Roland CAMM-1 series blade | |

| Offset | 0.000 to 1.500 mm (0.0 to 59 mil) | ||

| Software resolution (when cutting) | 0.025 mm/step (0.98 mil/step) | ||

| Media heating system (*3) | Print heater set temperature: | 86 to 95 °F (30 to 35 °C) | |

| Dryer set temperature: | 86 to 100.4 °F (30 to 38 °C) | ||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | ||

| Power-saving function | Automatic sleep feature | ||

| Rated input | 100-240 Va.c. 50/60 Hz 2.1 A | ||

| Power consumption | During operation | Approx. 185 W | |

| Sleep mode | Approx. 27W | ||

| Acoustic noise level | During operation | 62 dB (A) or less | |

| During standby | 60 dB (A) or less | ||

| Dimensions (Width x Depth x Height) | 42.1 in. × 24.3 in. × 24.5 in. (1,069 mm × 617 mm × 622 mm) | ||

| Weight | 137 lb. (62 kg) | ||

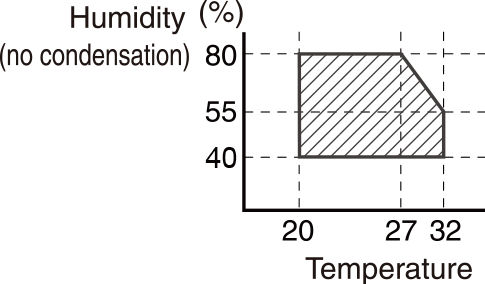

| Environment | During operation (*4) | Temperature: 68 to 82.4 °F (20 to 28 °C) Humidity: 40 to 80 % RH (no condensation) |

|

| Not operating | Temperature: 41 to 104 °F (5 to 40 °C) Humidity: 20 to 80 % RH (no condensation) |

||

| Included items | Power cord, media holders, replacement blade for separating knife, User's Manual, Software (FlexiDESIGNER VersaSTUDIO Edition, VersaWorks, Roland DG Connect), etc. | ||

| *1 | The length of printing or cutting is subject to the limitations of the program. |

| *2 |

|

| *3 |

Warm-up is required after power up. This may require 5 to 20 minutes, depending on the operating

environment. Depending on the ambient temperature and media width, the preset temperature may fail to be reached. |

| *4 | Operating environment (Use in an operating environment within this range.) |

|