DWX-52D Plus 5-Axis Dental Milling Machine

-

MSRP

$26,995 US*

* U.S. only. For Canada, Latin America and Caribbean pricing, please contact an Authorized Roland DGA Dealer in your area.

-

LEASE PRICE

$539.90 US**

** For 60 months, OAC

Apply Now

The industry's best dental mill just got better! The DWX-52D Plus has an all-new redesigned, upgraded spindle with 1.9x the gripping power for increased milling efficiency, expanded tool and material capabilities, and Intelligent Tool Control (ITC) efficiency.

Reliable Dental Milling Now Comes with Added Efficiency

DGSHAPE by Roland DG takes thirty-years of reliability and innovation and combines it with next-level production and efficiency to meet the needs of today’s growing lab businesses.

NEW DGSHAPE CLOUD Remote Management of All Current DGSHAPE Dental Mills from One Location

Enhance your business' ROI and minimize downtime with DGSHAPE CLOUD performance visualization software that allows for remote monitoring of the new DWX-53DC, DWX-42W, and all DWX-52D series mills from one location, desktop or mobile. The new, enhanced dashboard with artificial intelligence (AI) allows for remote monitoring of mill performance, productivity, mill maintenance, tool usage and more.

Click here to register for your FREE account today and learn more about our NEW DGSHAPE CLOUD Inventory Management Software.

Open-Architecture Platform

Allows users the flexibility to utilize their choice of restorative materials for dry milling, scanners, and CAD and CAM Software. Users can customize a workflow that is truly built to build their business.

For seamless CAM software integration with DGSHAPE DWX Dry Milling Solutions, users can rely on the trusted connection with hyperDENT-Powered by Roland DGA Edition CAM software or MillBox CAM software.

Discover growth in your dental business with the new advanced milling strategies today. For more information on product bundle discounts that include CAM software visit our promotions page.

Additional Features

|

Spindle 1.9x stronger gripping power than previous DWX-52D spindle |

|

|

5-axis Milling Ball screw-driven system with 5-axis positioning for simultaneous operation |

|

| Intelligent Tool Changer (ITC) Knows which tool to automatically swap out when tools have reached their designated lifespan |

|

| Virtual Machine Panel (VPanel) A user-friendly VPanel enables easy production and device monitoring – including auto calibration function |

|

Tool Sets Now compatible with 3.0 mm tool sets |

|

|

Ionizer Reduce static and dust when working with PMMA |

|

| Clean Milling Environment Mill clean with powerfully efficient internal dust collection and an automatic cleaning brush |

|

| Air Pressure Air pressure is automatically adjusted based on the CAM material data |

Additional Information

Specifications

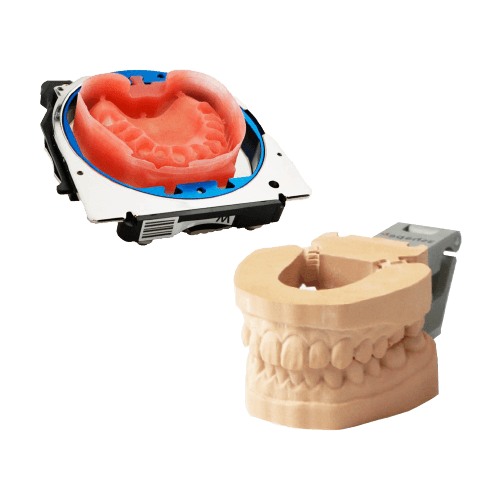

| Cuttable material | Zirconia, Wax, PMMA, Composite resin, PEEK, Gypsum, Glass fiber reinforced resin, Chrome Cobalt sintered metal | |

| Loadable workpiece shape | External Diameter | 98.5 mm |

| Max Height | 60 mm | |

| Step | 10 mm | |

| Pin Type Diameter | 6 mm | |

| Loadable workpiece weight | Up to 850 g | |

| Number of adapters housed | 6 | |

| Operating speed | XYZ axis: | 6 to 1,800 mm/min. (0.24 to 70.9 in./min.) |

| Spindle motor | Brushless DC Motor | |

| Spindle speed | 6,000 to 30,000 rpm | |

| Rotary axis travel angle | A axis | ±360° |

| B axis | ±30° | |

| Number of burs housed | 15 |

|

| Attachable bur | Shank diameter | 4 mm |

| Length | 40-55 mm | |

| Compatible compressed air | 0.05/0.2 MPa (Automatic switch) | |

| Interface | USB |

|

| Control command set | RML-1, NC code |

|

| Power requirements | AC 100 V to 240 V ±10%, 50/60 Hz, 2.0 A (overvoltage category II, IEC60664-1) |

|

| Power consumption | Approximately 200 W |

|

| Operating noise | During operation | 70 dB(A) or less (when not cutting) |

| During standby | 45 dB(A) or less |

|

| External dimensions | Width | 19.5 in (495 mm) |

| Depth |

26.0 in (660 mm) | |

| Height | 23.6 in (600 mm) |

|

| Weight | 147.7 lbs. (67 kg) | |

| Installation environment | Altitude | Up to 6,562 ft. (2,000m) |

| Temperature | 41 to 104° F 5 to 40° C |

|

| Humidity | 35 to 80% (no condensation) | |

| Ambient pollution degree | 2 (as specified by IEC 60664-1) | |

| Short-term temporary overvoltage | 1,440 V | |

| Long-term temporary overvoltage | 490 V | |

| Included items | Power cord, power plug adapter, USB cable, manuals, Roland DG software package CD, detection pin, automatic correction jig, pin-type material adapter, hexagonal driver, spanner, milling bur holders, milling bur positioner, dust collection hoses, dust collection hose adapter, regulator, cleaning tool, option adapter labels, material adapters, material adapter rack | |

| Operating system | Windows® 7/8/8.1/10 (32 or 64 bit) | |

| USB cable | Use the included USB cable | |

Brochure

Download DGSHAPE Product Line

Get your digital guide to all the features, applications, benefits and specifications of the Dental Mills

Download Brochure