Roland DG 3D Printing Improves Accuracy and Realism in Prosthetic Part Production

COMPRU | Edmonton Alberta, Canada

Roland DG 3D technology has dramatically improved the process for making medical prostheses. Rather than spending tedious hours hand sculpting, anaplastologists are now using the Roland DG desktop mill and 3D scanner to quickly produce prosthetic parts with improved accuracy and realism.

COMPRU – the head and neck reconstruction unit from the Caritas Health Group at Misericordia Community Hospital in Edmonton – is among the very first to take advantage of this new trend in facial reconstruction.

“Roland DG 3D technology has tremendous potential to impact the facial prosthetic field.”

“Roland DG 3D technology has tremendous potential to impact the facial prosthetic field,” said Rosemary Seelaus, COMPRU Anaplastologist. “It saves a significant amount of time hand sculpting so that I can quickly establish form and position. I can focus on the final details that make the prosthesis realistic. The technology preserves my clinical energy for the patient.”

The COMPRU team includes specialists in surgery, jaw and facial prosthetics, hearing, speech, dermatology, pathology, hyperbaric medicine, psychology, biomechanical engineering and radiology. Its members are leading edge providers of excellence in medical care, research and teaching. Seelaus is specially trained to make prostheses for the face with great realism and likeness to the natural anatomy.

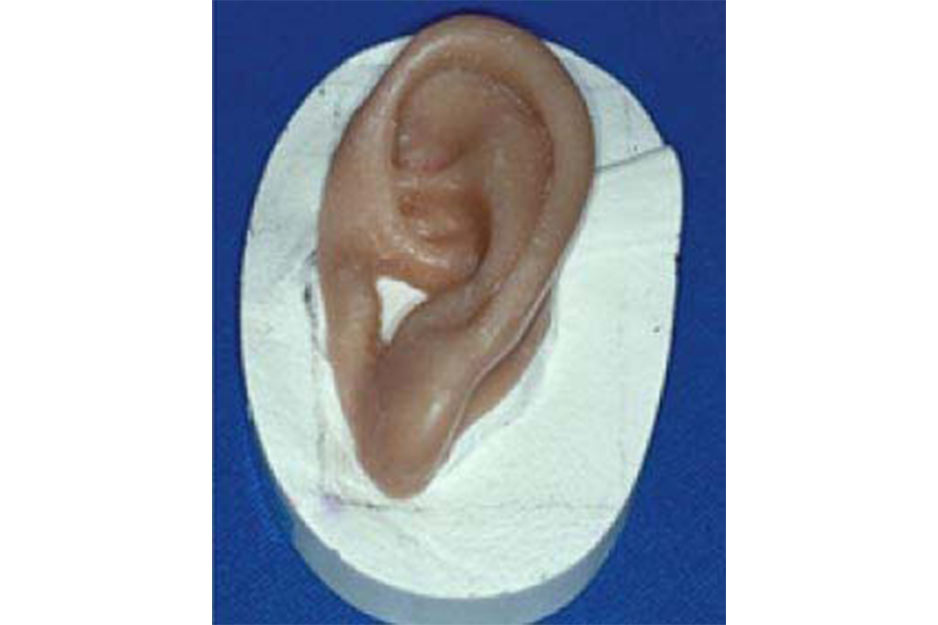

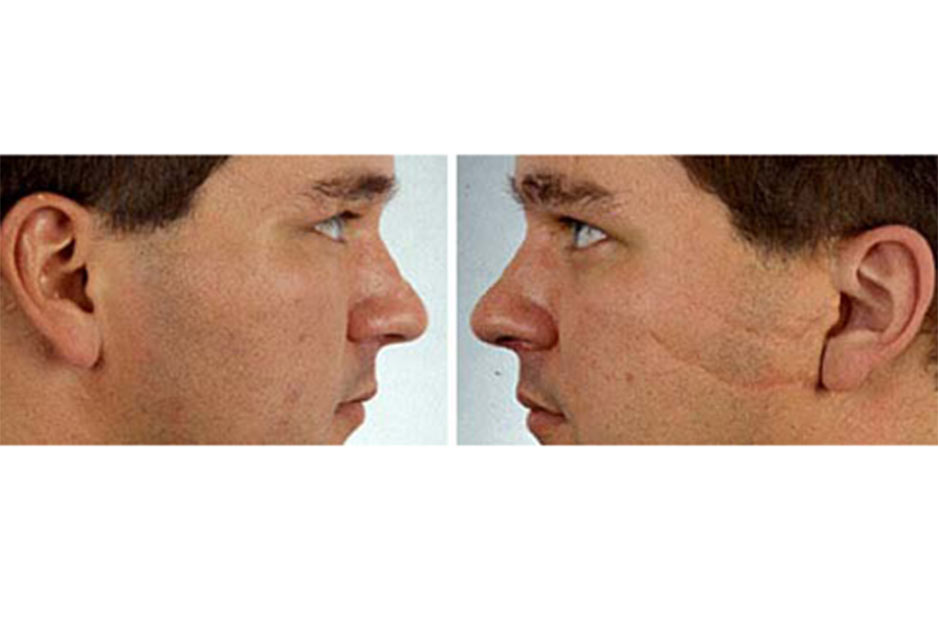

Seelaus recently made a prosthesis for a man who lost his left ear. Before using Roland DG 3D technology, she would create a plaster cast from an impression taken of the patient's existing ear and use its mirror image as a guide for hand sculpting the ear from modeling wax. This process was both long and tedious.

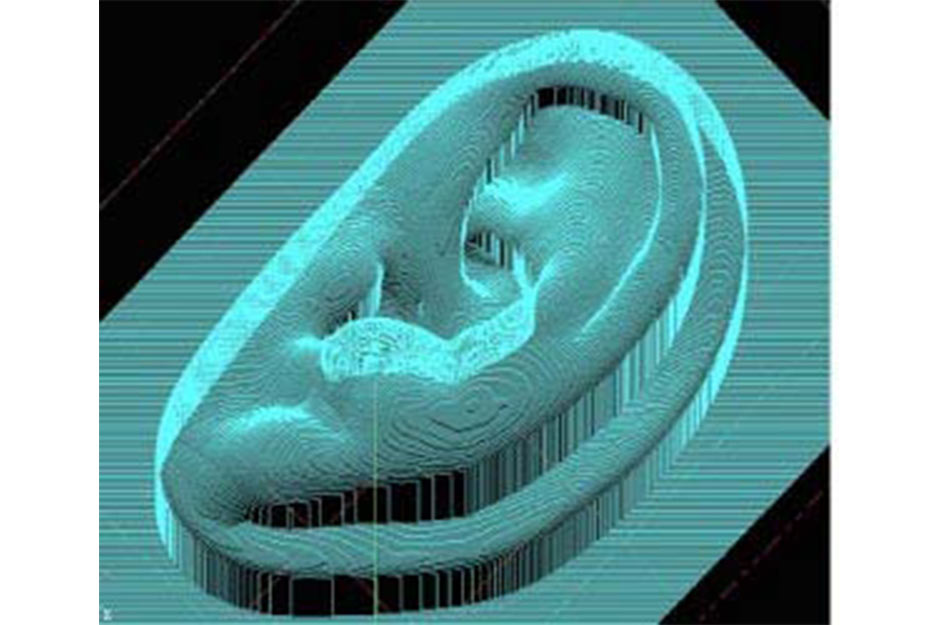

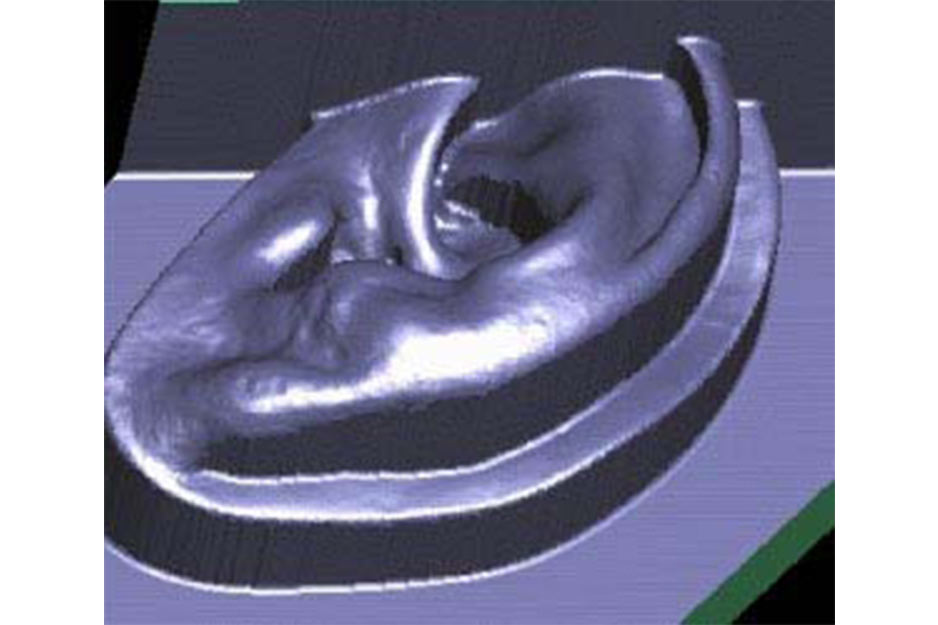

Today, she scans the plaster cast of the patient’s good ear with a Roland DG PIX-30, digitally mirrors the scanned file and mills it with a Roland DG MDX-650. This gives her more time with the patient to assess the ear model for accuracy, form and position. She duplicates the model by hand in a softer, flesh-tone wax to finalize form and fit on the patient. The prosthetic ear is now ready to wear, showing every wrinkle and pore in the skin.