LPX Scanners Allow for Unique Jewelry Inspired by Natural Textures and Shapes

Mark Esslinger

Mark Esslinger knows first hand that to succeed in today’s marketplace, jewelers must be able to offer unique pieces at good prices. Mark is CEO of Esslinger and Company, a Saint Paul, Minnesota, firm that sells equipment and supplies to jewelers nationwide. “The trend these days is toward more organic shapes and original designs," said Esslinger. “3D scanners are an affordable tool to help capture natural shapes that can form the basis for new jewelry lines."

As many jewelers can attest, attempting to duplicate natural textures and shapes using a CAD/CAM program often takes hours and typically yields designs that the human eye perceives as “mechanical." Purchasing a virtual library of scanned objects can be expensive and limits the designer’s creativity. Instead, Esslinger recommends his jewelry design clients consider purchasing a scanner to build their own inventory of scanned objects.

“The better the scanner, the smoother the image. With the Roland DG, you don’t have to spend time filling in missing data. It’s all there.”

To demonstrate the range of applications available within a single high quality scan, Esslinger recently scanned a strawberry using a Roland DG LPX-60 3D laser scanner. The LPX-60 can scan objects up to 12" tall x 8" wide at a maximum resolution of .2mm (.008"). Roland DG 3D scanners also come bundled with software that automatically sets the scan parameters and gives scanning times for the selected resolution. “Using the LPX couldn’t be easier. You place the object in the scanner and push start," said Esslinger.

Esslinger notes that when preparing to scan any natural object, it is important to select a well-shaped sample. To begin, Esslinger removed the leaves from the top of the strawberry. He commented that the leaves can be left on the fruit and scanned with the berry, or be removed and scanned separately later. A third option is to hand-create the leaves within the CAD/CAM design program. Esslinger then mounted the berry by inserting a small dowel in the core. He placed the dowel in the mounting putty that came with the LPX-60, thereby lifting the strawberry 1" above the floor of the scanner. In approximately 50 minutes, the unattended scanner produced a full 360-degree high-resolution image.

“Because the Roland DG scanners were initially designed for engineers and sculptors, they produce extremely detailed scans," said Esslinger. “The better the scanner, the smoother the image. With the Roland DG, you don’t have to spend time filling in missing data. It’s all there."

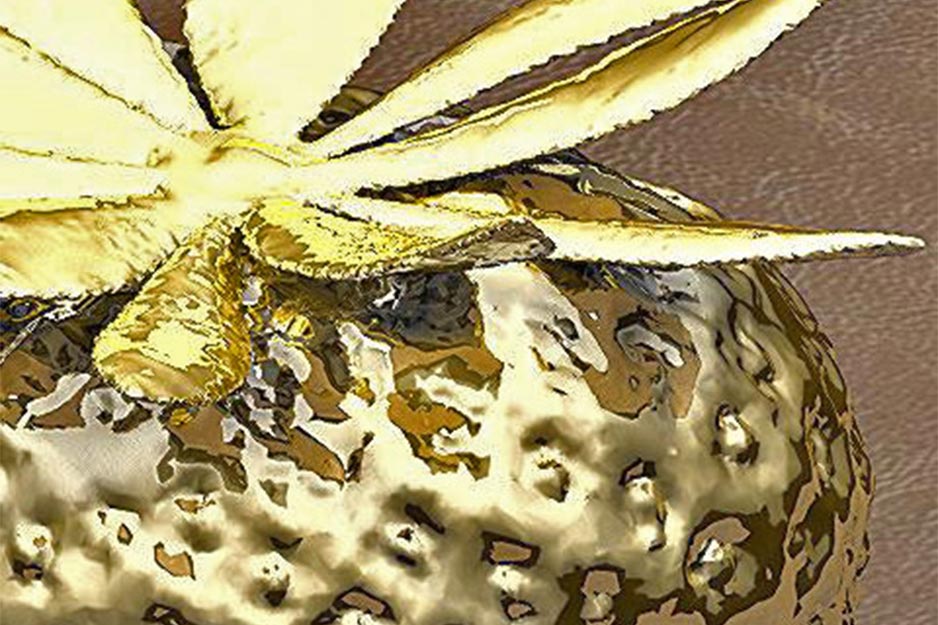

The LPX series includes software that prepares the scan data file for use in any of the popular CAD/CAM programs, including Rhino Gold, Matrix, ArtCam and 3Design. Esslinger exported his strawberry scan to 3Design, and was then able to scale the strawberry to a size suitable for a charm or pendant. He could also “open" or skew the strawberry, cut it in half, or use only part of the scan to create, for example, a relief on a pendant, disk or coin. To complete his image, he designed and added leaves, and added gold into the surface.

Esslinger notes that along with making organic shapes accessible to designers, the scanner can help the independent jeweler with inventory issues. “Many jewelers today can’t afford to stock the inventory they once did," said Esslinger. “Add to that the fact that customers are asking for custom pieces created from gold they provide, and having a virtual inventory of designs you can produce is invaluable."

The LPX scanners are able to handle a wide variety of organic and inorganic shapes. In addition to fruit, tree bark, rocks and other natural objects, small figures, carvings, and toys are also good candidates for 3D scanning. Esslinger knows jewelers who carve wooden figures, then scan them to create forms they can use in designing jewelry. “This versatility adds a lot to a designer’s ability to create unique jewelry lines as well as custom pieces," said Esslinger. He notes that even model airplanes and cars are easy to scan, saving designers hours of time on CAD/CAM programs. Other items of interest for scanning include family crests, religious items and heirlooms.

“Creating your own virtual inventory is a cost-effective way to ensure your designs are unique and attractive to today’s customers," said Esslinger. “for the jewelers I know who have developed lines from objects they scanned themselves, business has been very good."