ÜberBots: Un Programa Que Pone al Aprendizaje PRIMERO

ÜberBots | Avon, Connecticut

¿Cómo hacer que los jóvenes se emocionen con la ciencia y la tecnología? Este era el dilema que enfrentaba la Escuela Secundaria Avon en Avon, Connecticut. “Necesitábamos una forma de mantener el interés de los estudiantes y a la vez hacer que ellos apliquen su aprendizaje diario a desafíos de la vida diaria”, dice Jim Ligotti, fundador y director del programa de robótica de la escuela.

En el año 2002, la escuela recurrió a la ayuda de For Inspiration and Recognition of Science and Technology (Para la Inspiración y Reconocimiento de la Ciencia y Tecnología o FIRST), una organización sin fines de lucro que diseña programas para motivar a la juventud a estudiar carreras de ciencia, tecnología, ingeniería y matemáticas (STEM) y a la vez a obtener autoestima, conocimientos y habilidades para la vida.

Al comienzo, el programa era dirigido por los maestros, pero en una región con muchas empresas tecnológicas, los padres estaban dispuestos a asumir el liderazgo. Jim Ligotti y Paul Santasiero han sido los líderes desde el inicio del programa. Jim se involucró cuando sus propios hijos estaban en el programa, y Paul se unió luego de que sus hijos se graduaran. Ambos permanecieron debido al valor que el programa les daba a los estudiantes. Para darle al programa su propia identidad, el grupo eligió el nombre “ÜberBots.”

“Los estudiantes en verdad trabajan mejor en una comunidad grande de colegas, todos respetando el deseo de los demás de aprender y jugar con la tecnología. Queríamos hacer que la robótica sea algo atractivo para los chicos de manera que éstos estén interesados en estudiarla”, dice Ligotti. “Ahora los chicos tienen un grupo donde pueden hablar sobre la estabilidad de un bucle PID, ya que aún no se puede hablar de eso en la cafetería de la escuela”.

“ÜberBots ayuda a los estudiantes a desarrollar y aplicar conceptos básicos de ingeniería y matemáticas”, dice Ligotti. “Tener la MDX-40 de Roland DG nos permite llevar el programa a un nivel más alto, donde los estudiantes puedan crear diseños originales en la computadora y ver cómo las partes funcionan”.

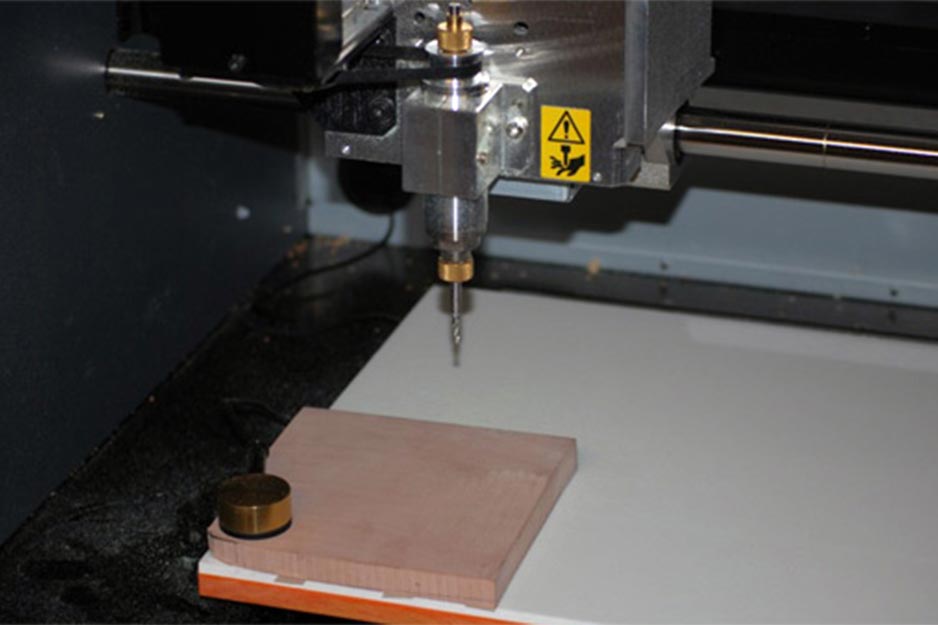

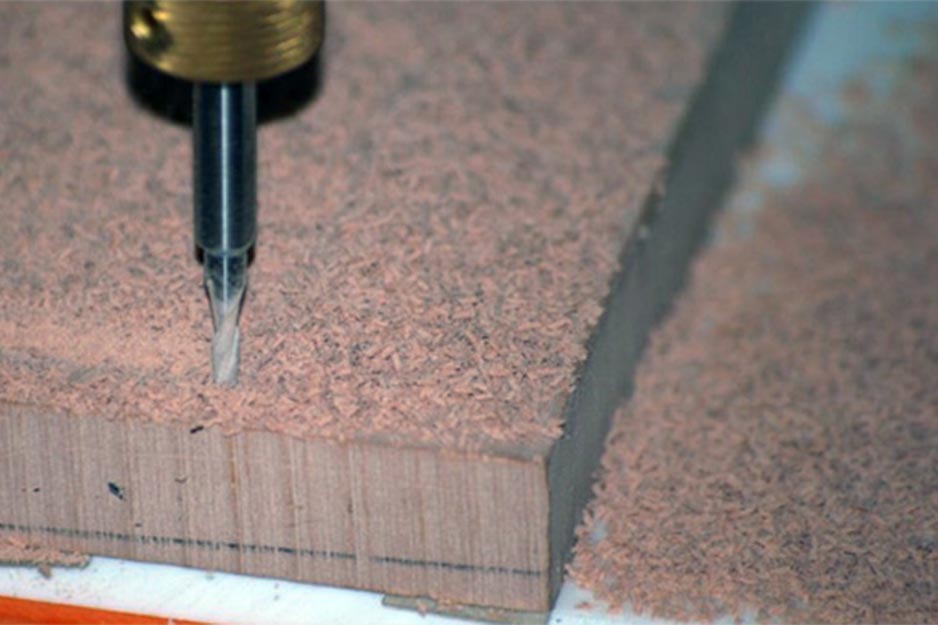

El programa ÜberBots recientemente adquirió una fresadora MDX-40 de Roland DG. “Tenemos una lista larga de deseos, pero esta máquina era el deseo número uno”, dice Ligotti. “La fresadora en verdad ayuda a los estudiantes a conectar teoría y práctica. Los estudiantes pueden en verdad crear lo que dibujan”.

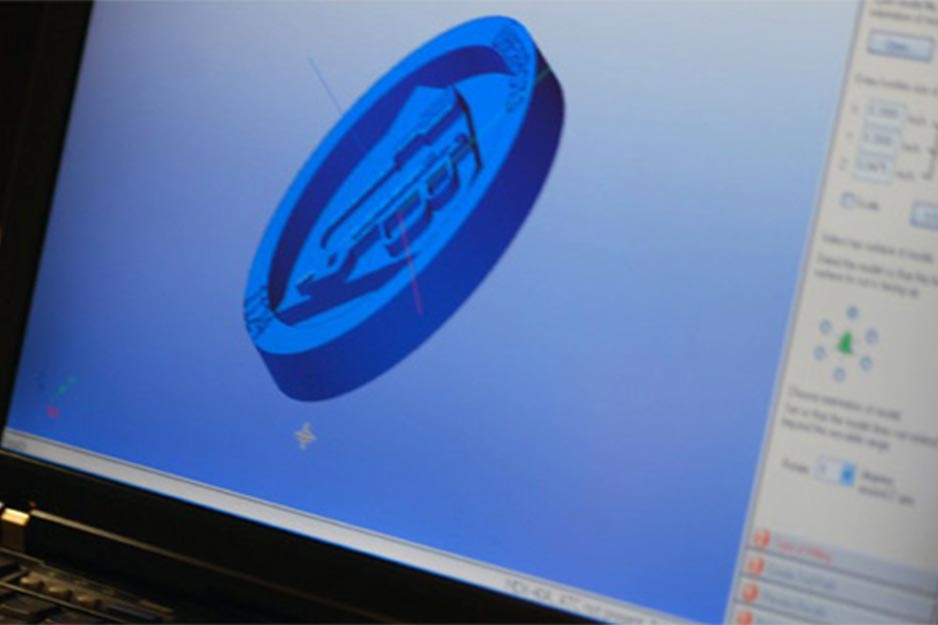

La fiesta de fin de año de ÜberBots estaba en sus etapas finales de planeamiento cuando llegó la fresadora Roland DG. Ligotti y Santarsiero desempacaron la máquina después de la clase con 20 chicos rodeándolos, esperando al menos calibrarla esa noche. “La guía paso a paso fue de muchísima ayuda. Usamos el software SRP para crear un marcador la primera noche”, dice Santarsiero. “Una semana después, los estudiantes habían diseñado y fresado el logotipo de ÜberBots en un molde de chocolate para los recuerditos de su fiesta”.

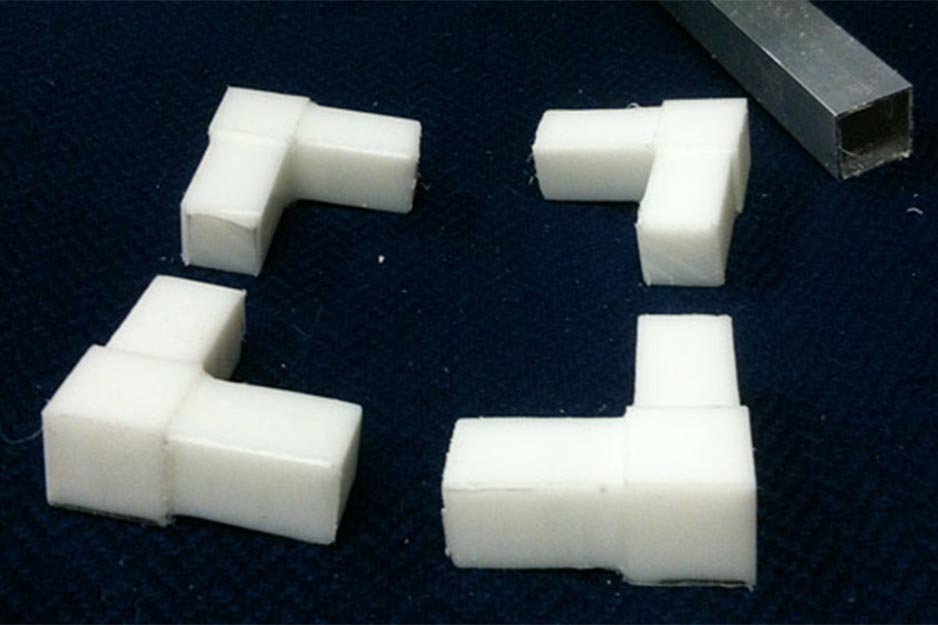

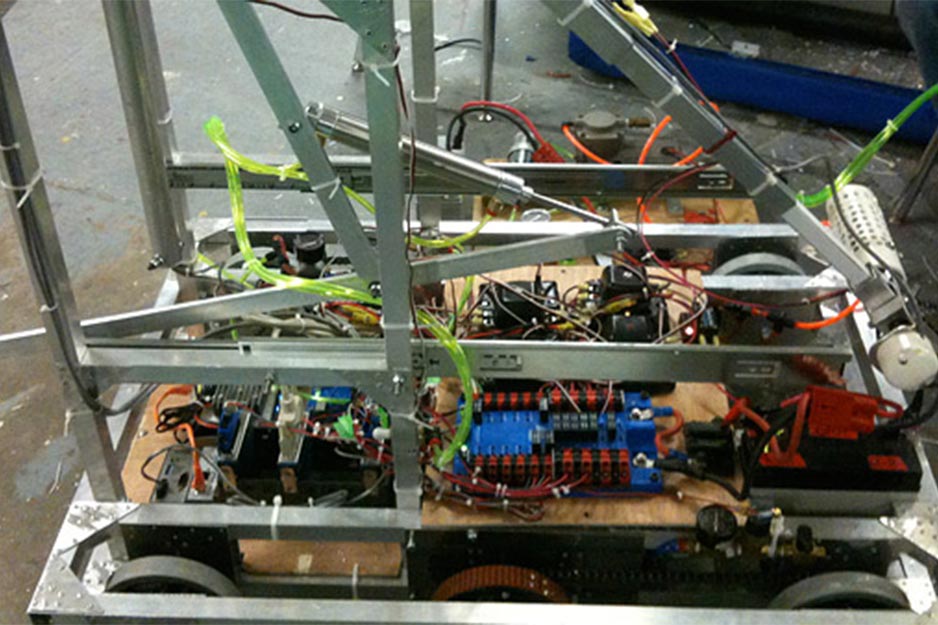

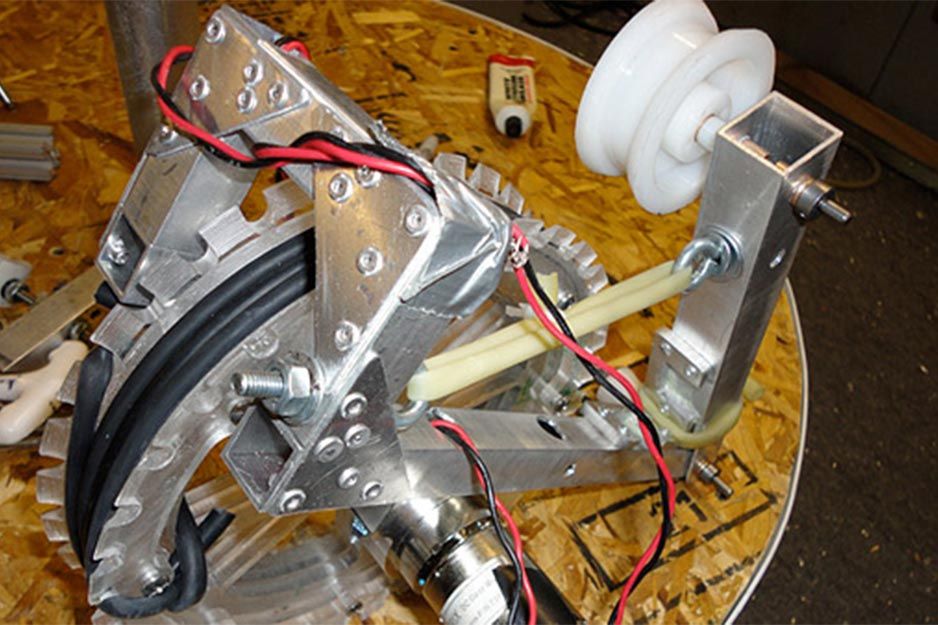

Los estudiantes de ÜberBots usan la MDX principalmente para fresar prototipos de partes para sus robots. “Nuestras otras herramientas eléctricas son una prensa taladradora y una sierra fija, así que el nivel de diseño que podemos obtener con la MDX es verdaderamente valioso”, dice Ligotti. Otra aplicación importante para el grupo es el diseño de los separadores de plástico para la variedad de componentes electrónicos en el robot. “Trabajamos muy en serio con los estudiantes para entender los aspectos prácticos del diseño”, dice Santarsiero. “El eje articulador que dibujan en la pantalla tiene que alojar la cabeza de perno sobresaliendo por encima”.

Actualmente hay aproximadamente 50 estudiantes en el programa, incluyendo un número cada vez mayor de chicas. Los exalumnos del programa se mantienen involucrados a través de un sitio Web interactivo, ofreciendo consejos a los estudiantes más jóvenes a medida que enfrentan desafíos presentados cada año en las directrices de fabricación de robots de FIRST.

“Proporcionamos lo que los talleres de metales y madera solían proporcionar: aprendizaje práctico”, dice Santarsiero. “Los estudiantes ven al robot caerse, y les ayudamos a pensar en cómo reconstruirlo.”

Cada año, los estudiantes traen su robot a competencias regionales, donde compiten contra una cantidad de entre 50 a 60 equipos. Las aplicaciones adicionales para la MDX incluyen el diseño de recuerdos de plexiglás tales como botones o tarjetas para intercambiar con otros equipos. También usan la máquina en el fresado de trofeos iluminados para premiar los esfuerzos de los estudiantes.

“ÜberBots ayuda a los estudiantes a desarrollar y aplicar conceptos básicos de ingeniería y matemáticas”, dice Ligotti. “Tener la MDX-40 de Roland DG nos permite llevar el programa a un nivel más alto donde los estudiantes puedan crear diseños originales en la computadora y ver cómo las partes funcionan”.