One of the most common questions that we get at trade shows and from inbound phone/email leads is this: “What materials do your machines use and where can I buy them?” One of the key advantages of SRP is the ability to use a very wide range of materials. The fact that the materials are not proprietary and can be purchased on the open market keeps the cost of ownership for Roland DG SRP machines low. Here are some resources available:

Craigslist: This is a great resource for a wide range of materials, including plastics, woods and metals. Since SRP machines don’t use giant pieces of material, many times industrial scrap is a great way to buy smaller sized pieces that will fit into the machine. Since you are sourcing them locally from Craigslist, you can save on shipping costs and meet the seller face to face. Maybe they will have more scraps next month that you can take off their hands. www.craigslist.org Search for the specific material you need: Acetal, Nylon, Acrylic, Oak, etc.

Freeman Supply: Freeman supply offers plastics, casting materials, urethane boards and cutting services to supply you with specific materials cut to specific block sizes. You can visit them on the web at www.freemansupply.com

Ebay: For industrial scrap, a good source is Ebay. Just search for the material you need. Many times a material will be listed by its generic resin name IE: Acetal or by a specific brand name: Delrin.

Material Overview:

Sintra PVC foam board is used mainly in the sign industry. It is available in a wide range of colors and thicknesses and is used to quickly cut flat parts that can be assembled into 3D objects. The material is light, relatively strong and inexpensive, which makes it great for educational applications, form studies, flat pack designs, etc. Google “Sintra PVC” to see examples and a wide range of suppliers.

Acetal (one brand name is Delrin) is one of our favorite plastics for prototyping. It machines extremely well, holds tight tolerances, remains dimensionally stable and is self lubricating. It is great for tough plastic parts like the MDX-40A fan blade. Acetal is used for a wide range of prototyping and manufacturing applications, including rollers, bearing blocks, fixtures/jigs, enclosures, etc. Acetal can be purchased from plastic supply houses, but less expensive options are on Craigslist or Ebay.

Renshape is a brand name of urethane board made by Huntsman. It is also referred to as tooling board, butter board, renboard, chemical wood, Sanmodur, etc. Renshape is available in a wide range of densities, from soft foam that you can dent with your finger to aluminum-filled epoxies for short-run injection molds. Renshape is great for form studies, appearance models, tool path verification and urethane molds or master patterns for rubber molds. Renshape is available from plastic supply houses like Freeman Supply. You can order a sample kit from Freeman to get a good feel for the different material weights available. At Roland DGA, we like to stay away from the ultra light weight versions since they create a lot of dust that goes everywhere. The peach colored version is good for quick form studies while the medium weight versions are good for most applications and are typically a pinkish brown color. Renshape selection chart.

Other Materials to Consider:

Extruded styrene sheet: If you live in a colder climate you can purchase extruded styrene insulation sheets at Home Depot or Lowes. They come in 2’ x 8’ x 2” thick sheets and cost about $15. This is a great material for low-cost models that are light and buoyant. It’s great for school projects, architectural terrain models, form studies, etc. Product overview.

Hard Woods: You can visit Home Depot and find open boxes of oak or other flooring strips. For about $10, material can be purchased that is great for signs, wood models and more.

Polystyrene foam: Polystyrene foam can be milled on a Roland DG MDX mill as well, to achieve the soft surface textures and flexibility for custom medical, sports or footwear applications

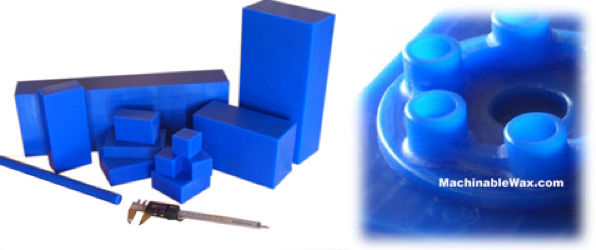

Prototype with Wax for Easy, Precise Results

A great material for prototyping parts is wax. It cuts easily, holds details and is very easy on tooling. You can also melt a project down and recast it into a block to use again! But you can’t use just any wax. You must use wax that is formulated for CNC machining. Fortunately, there is a source for machinable wax on the web that offers a range of sizes and will cut to size as needed: www.machinablewax.com