VIVAS Inc. Adds High-Performance Resin Ink Printer for High-Volume Printing

VIVAS Inc. | San Francisco, California

Luis Vivas, founder and CEO of San Francisco, California-based VIVAS Inc., always knew he’d succeed. Luis started his print business in 2012 from his apartment, with dreams of making it big. Over the years, his hard work, dedication, and pursuit of excellence paid off. Today, VIVAS Inc. provides interior and exterior branding, event signage, and wraps for some of the best-known companies in the world, including Lucas Film, Google, Facebook, Nike, Sephora, and many more.

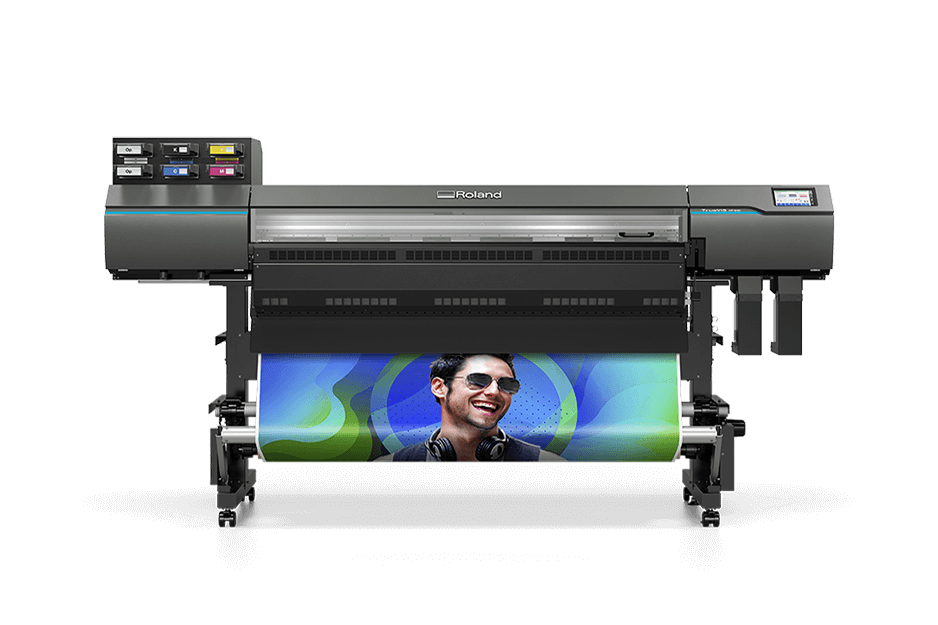

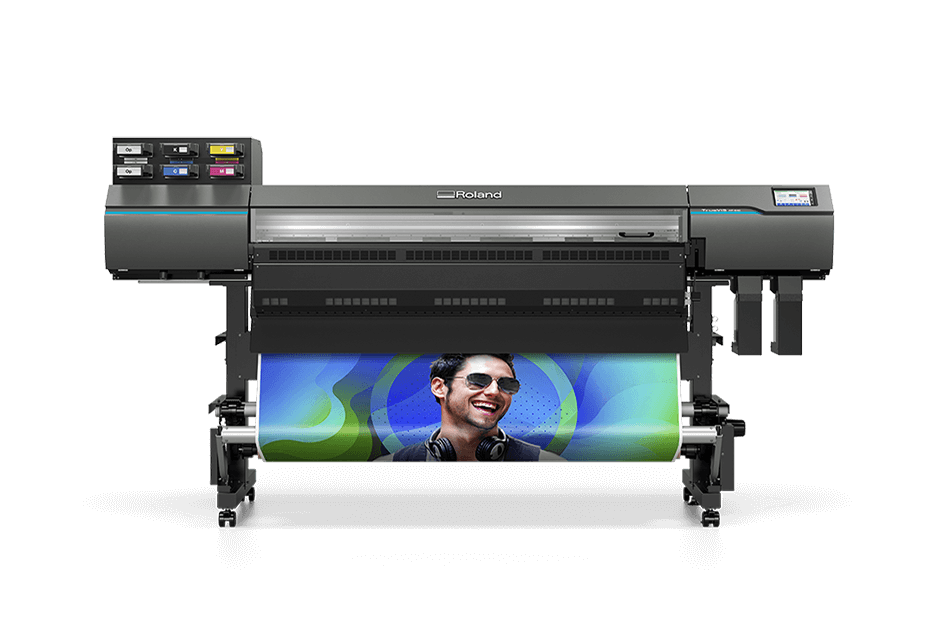

VIVAS Inc. recently added Roland DG’s TrueVIS AP-640 resin/latex ink printer to its production room. We asked Luis about why he chose to bring in a resin ink printer, what types of projects he’s using this versatile production printer for, and how having resin ink printing capability enhances his offering to clients.

Tell us about VIVAS Inc. today.

Luis Vivas: We are pleased to be extremely busy, serving a steady stream of new clients as well as our returning clients. In recent months, we’ve been fortunate to work with forward-thinking companies like Disney and Pinterest, as well as with outstanding universities such as UC Berkeley and MIT, and amazing charitable organizations like Meals on Wheels.

“Resin ink printing is excellent for producing interior graphics, especially in places that require low VOC emissions into indoor air, like schools, hospitals, and healthcare facilities.”

Our staff of seven works in our 3,000-square-foot facility with our Roland DG equipment, including the new TrueVIS AP-640 64-inch resin ink printer, a TrueVIS VG3-640 64-inch eco-solvent printer/cutter, a TrueVIS VG2-640 eco-solvent printer/cutter, and a VersaUV 64-inch UV printer.

Why did you decide to add the TrueVIS AP-640 resin ink printer to your production room? What features were most important to you?

We knew we wanted to add resin/latex ink printing capability, for several reasons. Resin ink printing is excellent for producing interior graphics, especially in places that require low VOC emissions into indoor air, like schools, hospitals, and healthcare facilities.

Print production speed is also key for us. Since resin ink output doesn’t need to outgas, we save a lot of time, especially when we need to laminate the prints before installation. It’s great for high-volume printing projects like fleet vehicle graphics, since the inks dry almost instantly and we can move on to lamination and installation without delay.

I decided to add the Roland DG AP-640 resin ink printer because I have always trusted Roland DG's products to provide outstanding output with unmatched reliability. Having latex printing capability elevates the quality of our production and provides options for serving our clients. In addition, we are working to launch our own brand of custom wallcoverings, which is a perfect application for resin ink.

How has the AP-640 performed for you?

We have been extremely pleased with the quality of the output from our AP-640. Quality is always important for my customers, large or small. So far, we have used the AP-640 on projects for some of our highest-profile clients, including Lucas Film, Disney, Sephora, UC Berkeley, National University of Singapore, SBA, Pinterest, and Meals on Wheels.

My clients always care about the accuracy of their brand colors. We’ve been using Roland DG printers since 2015, and we know that with Roland DG technology, we have the wide color gamut and range of profiles we need to deliver excellent color across platforms.

Over the years our clients have come to trust our expertise and understand that we use the best printers in the industry. As a result, they allow us to run their branding graphics without color proofs. That would probably be risky for most sign shops, but we know we can rely on our Roland DG printers to deliver great color results. My clients always smile when they see their spaces.

The AP-640 is now part of that trust with our clients, giving them the confidence that we will produce accurate resin ink color. Our customers save a lot of time with color matching by working with VIVAS.

Tell us about your recent work for the National University of Singapore (NUS).

NUS has been our client since 2016. In 2023, they opened a new location in Palo Alto, California. This branding project had an extremely tight turnaround deadline of three days.

We used the AP-640 to produce five wall graphics on 3M 40C media with Luster overlaminate. By using resin ink, we were able to laminate the prints right away, which enabled us to deliver and install the graphics on time. As usual, we also had to match Pantone colors, which was no problem with Roland DG’s wide color gamut. My clients were very pleased with the results.

How is having resin ink printing capability changing your business?

The AP-640 is definitely changing the way we see interior décor. My clients want to elevate their interior design by applying beautiful custom prints to their walls. With our Roland DG resin ink printer, we are able to make it happen.

What would you tell someone who is considering a resin/latex ink printer?

I have been in this business for over a decade, and I love being able to use eco-solvent ink, UV ink, and resin ink as each project requires. Resin ink not only provides great quality and speed for our clients, it’s also a great fit for our staff. The printer is very easy to work with, produces less media waste, saves a lot of time, and is easy to set up with Roland DG’s impressive VersaWorks RIP software.

Resin ink printing is the technology of the future and having the Roland DG AP-640 resin ink printer at VIVAS Inc. helps us stay on the cutting edge, while maintaining our reputation for high-quality output.