MDX-540 Offers Unmatched Precision and Wide Selection of Substrates, Perfect for Medical Prototyping

Joe Matteo

Ask inventor and successful entrepreneur Joe Matteo why he chose Roland DG’s subtractive rapid prototyping milling machine and he’ll start by naming the many substances the MDX-540 table top mill can process. “The driver for me was the broad choice of materials. I wanted to use the parts produced as actual prototypes, so I was looking beyond fit and finish,” said Matteo. “With the MDX, I can machine our devices in, for example, aluminum, Delrin, Teflon and PEEK to test the best material for our applications.”

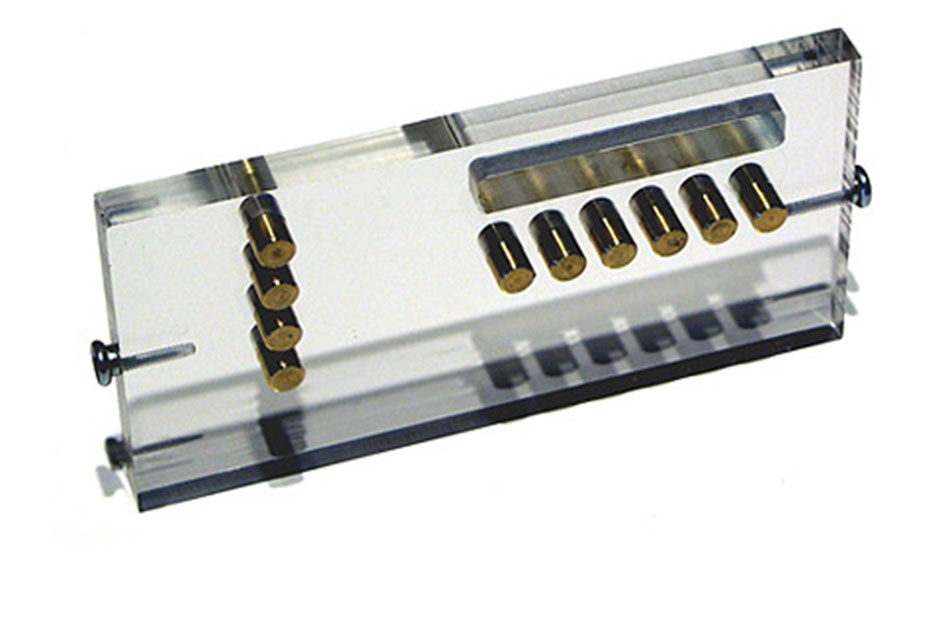

Mr. Matteo was the founder and president of NanoTek, LLC, where he lead the development of microfluidic instruments for rapid synthesis of radiolabeled compounds for function medical imaging. NanoTek, acquired by Advion BioSciences, Inc., is the scientific leader in microfluidics systems for chemistry and biochemistry applications and produces instruments for microfluidic synthesis of tracers or radiolabeled imaging agents used for diagnostic testing, primarily for cancer. Their instruments use micro-scale channels and micro reactors to rapidly optimize and produce imaging tracers. Until recently, Mr. Matteo served as Advion’s chief technology officer, but left to pursue development of new instrument technologies as an inventor and entrepreneur once again.

Manipulating solutions at the micro or nano scale brings with it the benefit of enhanced chemical properties. However, to achieve these properties, scientists must manipulate very small volumes at very high pressure. Maintaining pressures as high as 1000 psi (pounds per square inch) requires that the prototype parts have extremely accurate fit and finish to create tight seals. “I’ve been very impressed with the accuracy of the milling. The seals I can create using the MDX-540 are tight enough for us to actually use the prototype to run the experiment,” said Matteo.

Since these demanding applications require that the devices endure organic solvents, high temperatures and high pressure, Matteo seeks a balance of material properties in the materials he mills. To accelerate the prototype-to-production process, Matteo frequently mills a single prototype from several different materials. “I’ve made the same part with polysulphone, Teflon and PEEK - tested at temperature, under vacuum and using organic solvents. Then we use the part in our experiments to see which one performs best. This allows us to refine our own process pretty rapidly,” said Matteo.

“The seals I can create using the MDX-540 are tight enough for us to actually use the prototype to run the experiment.”

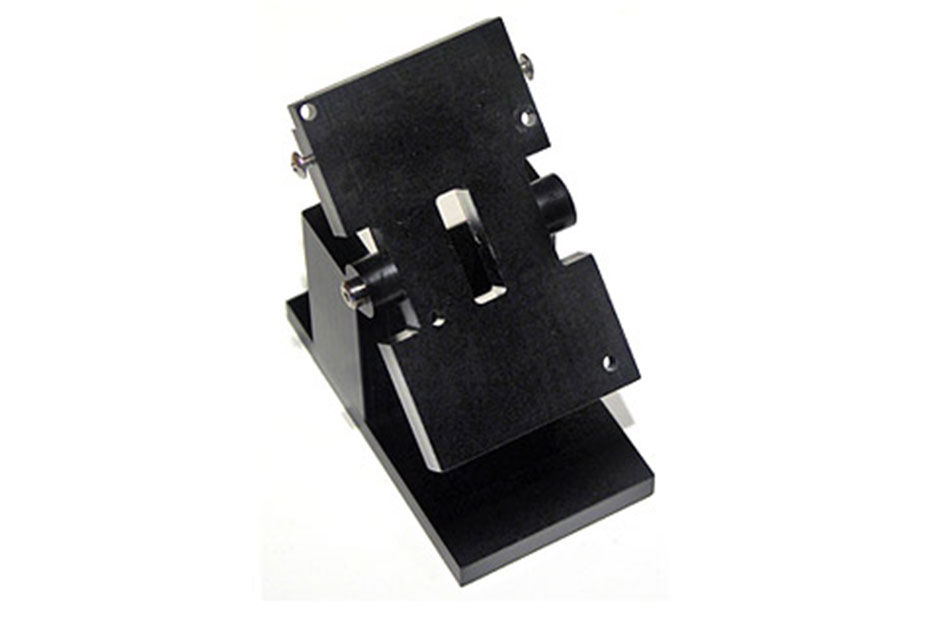

Materials that have the required strength can withstand high temperatures, are chemically inert and are not inexpensive in general that is why Matteo appreciates being able to minimize material waste when milling. He has built a fixture for the MDX-540 that allows him to use a block of material that is only 0.500” longer than the part he’s milling and 0.050” wider and thicker. To speed setup and reduce waste, Matteo uses the MDX’s Handy Panel and Virtual Panel to guide the machine and locate the center origin.

Matteo also uses the MDX-540 bench top mill to produce multipart molds, laying out the design in SolidWorks for a single assembly and then manufacturing the entire mold in one production run. Matteo values the MDX-540’s reliability and excellent performance, and often maximizes his work schedule by running the machine overnight or on the weekend.

“The accuracy has been critical to our success,” said Matteo. “The machine’s precision is incredible. I can create a slip-fit or a press-fit without hesitation.” The parts Matteo mills are generally square or rectangular shapes ranging from two inches to six inches in length. Matteo uses Roland DG’s MODELA software to program his complex designs into the MDX-540, many of which require drill holes in the range of 0.020” in diameter to accommodate glass capillaries of still smaller diameters.

“Reducing costs and increasing the number of iteration cycles in the development process is critical for high technology products to be successful. The process of product development is really accelerated by having this machine. It has allowed me to cost effectively make parts I wouldn’t previously consider attainable. The versatility and accuracy are outstanding,” said Matteo. “I rely on the MDX-540 bench top mill to get our products to market quickly.”