Fabrication Lab Spurs STEM Learning

Willoughby Eastlake | Willoughby, Ohio

As STEM education efforts have grown across the country, many school districts are responding with far-reaching solutions. Ohio’s Willoughby-Eastlake School District took an “all-in” approach – starting its own School of Innovation for grades 3-8.

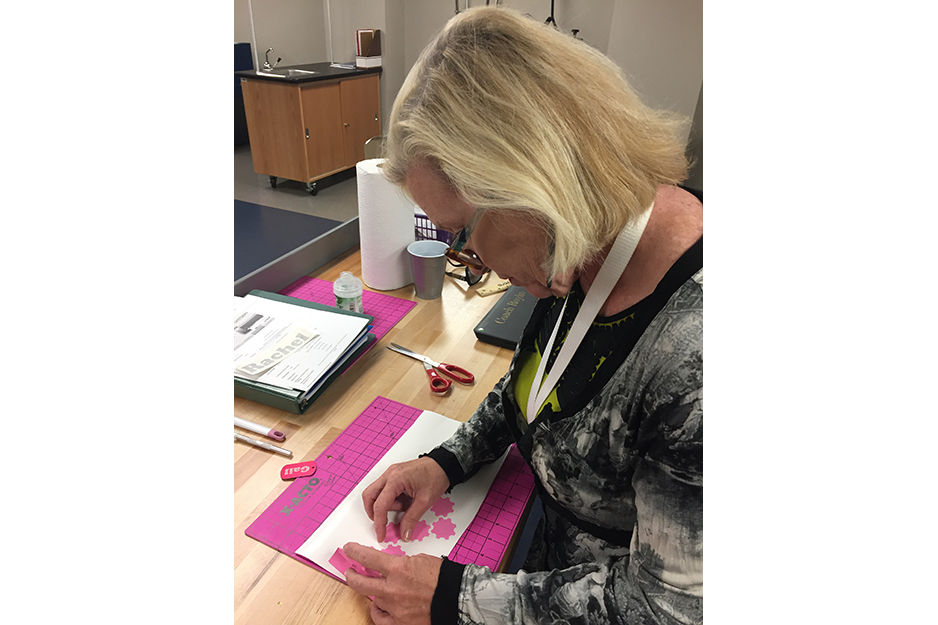

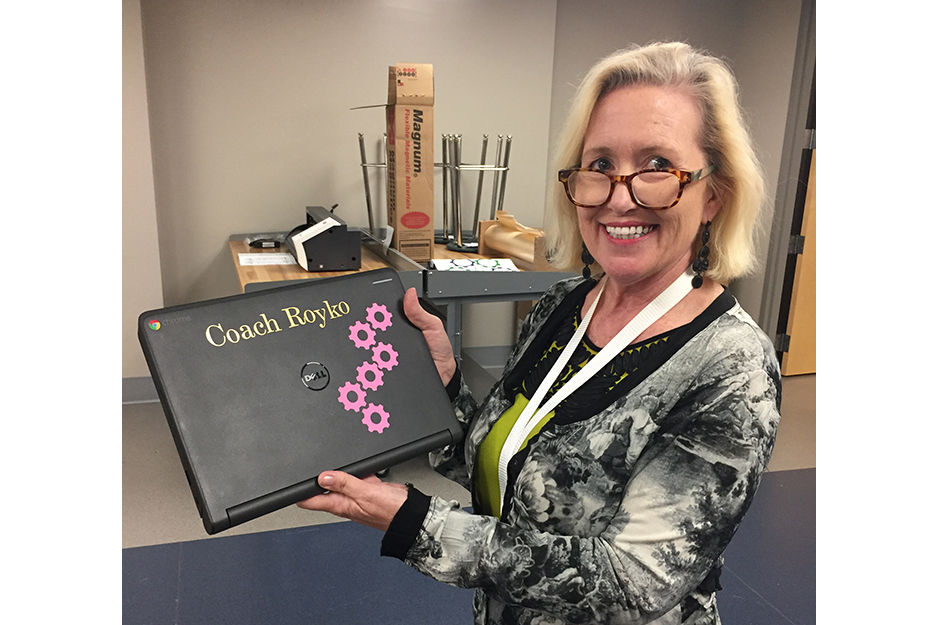

Longtime elementary school educator and MIT-certified Fab Lab Specialist Rachel Legerski is amazed at what her students can do. “We started a Fab Lab five years ago, and the students’ progress has been incredible to watch,” she said.

Equipped for Success

Since 3rd – 8th grade students represent a wide range of abilities, the Fab Lab needed robust, easy-to-use equipment. Along with lasers and 3D printers, Legerski’s Fab Lab relies on Roland DG’s TrueVIS SG-540 54-inch digital printer cutter, VersaStudio BN-20 desktop printer/cutter, and CAMM-1 large format vinyl cutter.

“I had zero prior experience with digital printing technology. I can tell you that the Roland DG equipment is truly user friendly,” said Legerski. “All of the kids can use the Roland DG equipment.”

Younger children start by creating decals and simple vinyl cut labels for labeling coat racks, bins, and lockers. Older students designed posters, decals and T-shirt graphics. The students have also made personalized ornaments for the holidays.

Project-Based STEM Learning

The School of Innovation’s project-based learning format challenges students of all grade levels with a problem to solve.

Legerski has also created directional and wayfinding signs for school buildings. “As people are becoming aware of what we can do, we have more and more requests coming in,” she said.

Planning for the Future of STEM

Legerski is looking forward to trying new projects with her students, including vehicle graphics. In the fall, the middle school plans to open a pop-up shop to sell decals and posters.

Legerski is also working with administrators to eventually develop a student-run print shop. “We’d love to be able to generate some revenue for our program,” she said.

Longtime elementary school educator and MIT-certified Fab Lab Specialist Rachel Legerski is amazed at what her students can do. “We started a Fab Lab five years ago, and the students’ progress has been incredible to watch,” she said.

Equipped for Success

Since 3rd – 8th grade students represent a wide range of abilities, the Fab Lab needed robust, easy-to-use equipment. Along with lasers and 3D printers, Legerski’s Fab Lab relies on Roland DG’s TrueVIS SG-540 54-inch digital printer cutter, VersaStudio BN-20 desktop printer/cutter, and CAMM-1 large format vinyl cutter.

“I had zero prior experience with digital printing technology. I can tell you that the Roland DG equipment is truly user friendly,” said Legerski. “All of the kids can use the Roland DG equipment.”

Younger children start by creating decals and simple vinyl cut labels for labeling coat racks, bins, and lockers. Older students designed posters, decals and T-shirt graphics. The students have also made personalized ornaments for the holidays.

Project-Based STEM Learning

The School of Innovation’s project-based learning format challenges students of all grade levels with a problem to solve.

“All of the kids can use the Roland DG equipment”

One of the school’s recent projects was to inform the community about efforts to reclaim the wetlands located behind the school. Fifth grade students used the BN-20 to produce informative posters about invasive species. Older students created posters with additional detail on reclamation projects. “It was so exciting to see the kids working together, and to see their finished products,” said Legerski.Legerski has also created directional and wayfinding signs for school buildings. “As people are becoming aware of what we can do, we have more and more requests coming in,” she said.

Planning for the Future of STEM

Legerski is looking forward to trying new projects with her students, including vehicle graphics. In the fall, the middle school plans to open a pop-up shop to sell decals and posters.

Legerski is also working with administrators to eventually develop a student-run print shop. “We’d love to be able to generate some revenue for our program,” she said.