The VersaOBJECT MO-240 UV Flatbed printer was introduced at the beginning of 2024. I love the simplicity, dependability, and exceptional image quality that the MO provides. For this Quick Tip, I thought I would share a few quick pointers to help simplify MO-240 installation and make using this innovative device even easier.

Quick Tip #1: Moving the MO-240 in your Workshop

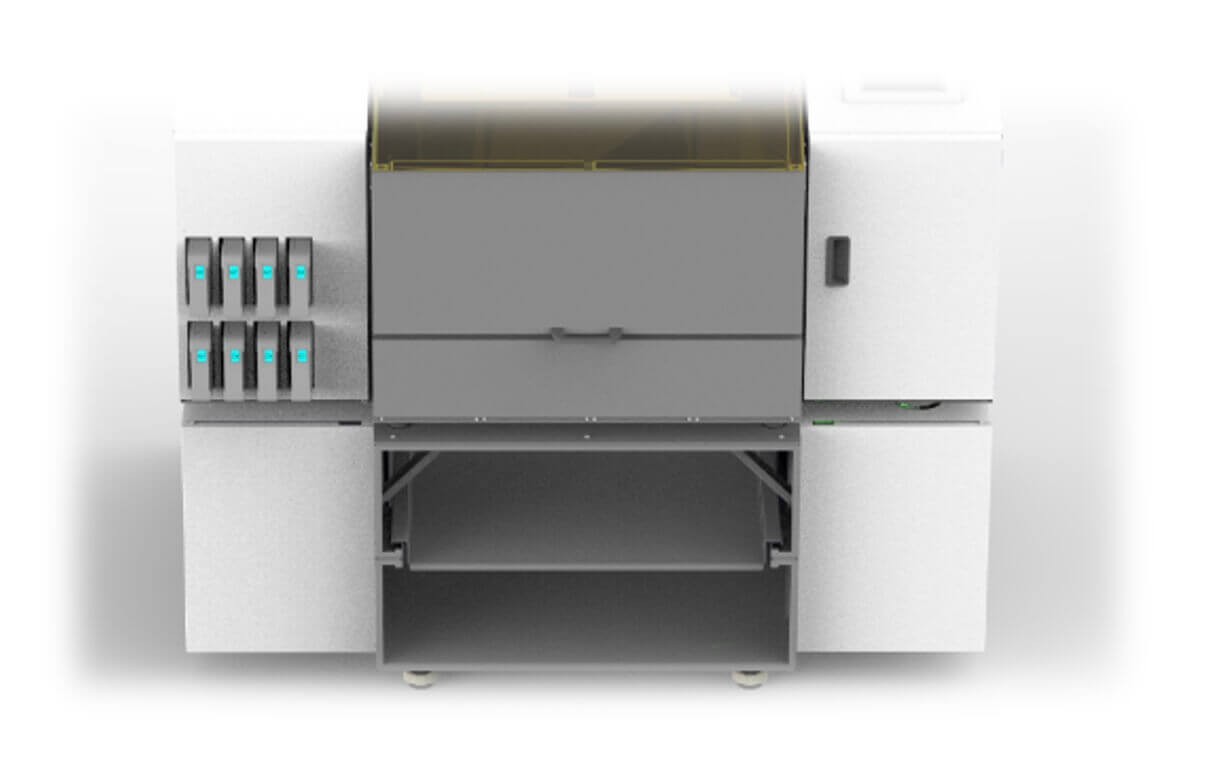

The MO-240 is made for production and has a robust steel frame that can handle multiple shifts per day. As a result, our new baby tilts the scales at 464 pounds. If you want to move the MO-240 through a narrower entry, there are a couple of options:

-

Place the MO on its back:

This allows the heaviest area of the printer to be supported and provides a profile of 28.5 inches for more narrow entries.

-

Place the MO on the cart/dolly with Ink Cartridge side on the bottom: This provides you with the same 28.5” profile, but it makes it easier to go around corners.

If you are manually lifting the printer, it is recommended that you have six people assisting you to safely position the MO-240.

Quick Tip #2: Stand Assembly Suggestions

The MO-240 was specifically designed for heavy-duty output. As a result, there is a fair amount of assembly required to construct the 342-pound steel frame for both the Standard and Basic Stands. To facilitate this process, here are some helpful suggestions:

- in advance and keep it handy during the assembly.

- Consider using an electric screwdriver and rachet wrenches.

- Some of the stand covers have additional holes for other product designs. Take care to ensure the correct placement of the screws.

- Do not fully tighten the sheet metal cover sheets until the frame is fully straight.

- The Charcoal Filter is a cube that is made with fabric. It looks like a metal box in the manual.

- Anticipate a 2-hour assembly time.

Here is some additional information on the MO-240 Stand design that may interest you:

- The new Air Filtration Device is made by ULT (not BOFA).

- The MO-240 Stand design significantly reduced the price from the LEF design.

- The MO-240 Standard Stand with Air Filtration uses one-third the power of the LEF design.

- The Air Filtration is fully automated.

- The Air Filtration system is silent, so it will not add to noise of your workshop.

Quick Tip #3: Printing with Primer and White Ink in the Same Layer

While the steps for printing Primer and White is the same with the LEF and the MO-240, there may be some confusion about the process, especially among new users. Primer and White are both Special Colors and “take turns” in entering information in VersaWorks. We start with Primer and then add White. Here is a quick reminder on how to set this up:

-

Double click a file to open it and select the “Quality” category:

- Select “Generic with Primer” Media Type

- Select “Primer -> White” for the ink Mode

-

Go to the “Special Color” category at the bottom of the list of categories:

- Check “Generate Special Color Plate.”

- In Special Color change “Primer” to “White.” and re-check “Generate Special Color Plate.”

- Under the “Special Color Plate Correction” section, change the Special Color to “White.”

-

Click “OK” in the bottom of the screen

If you go back into the program, you can open the Special Color category and toggle between Primer and White.

If you have any questions or suggestions, please contact me!