“Media Reflective Intensity” is a term you may have noticed creeping into your UV product menus as well as the occasional conversation in UV flatbed circles. People have long been puzzled as to why some UV printers go through their printheads more quickly than others. Of course, printhead wear is mostly due to the amount of production the printers crank out, but that wasn’t always the case. Through tedious inspection of the entire print process, Roland DG’s engineers were able to determine one of the key links to the premature failure of UV printheads – you guessed it, Media Reflective Intensity.

It was discovered that the UV light can sometimes kill a printhead sooner than expected when there is a marked increase in reflectivity in the printing process. A UV light wave operates in a similar way as a sound wave. You can reflect (echo) sound when you’re standing next to a rock wall, although it doesn’t echo particularly well when you are directing it to a small rock. The same thing goes with UV light.

While a small, flat, dark shape doesn’t have much of an impact on reflecting light, a large glittery object – let’s say a clear acrylic trophy – it’s going to significantly magnify the UV exposure in a UV flatbed printer. Since we add an enclosure to protect people from UV light, the impact is further magnified when the light reflects off the walls of the printer cabinet. The reflection of UV light coming from every direction in the printer results in the accelerated curing of the ink in and on the printhead. The more RI, the more the printhead needs to be cleaned.

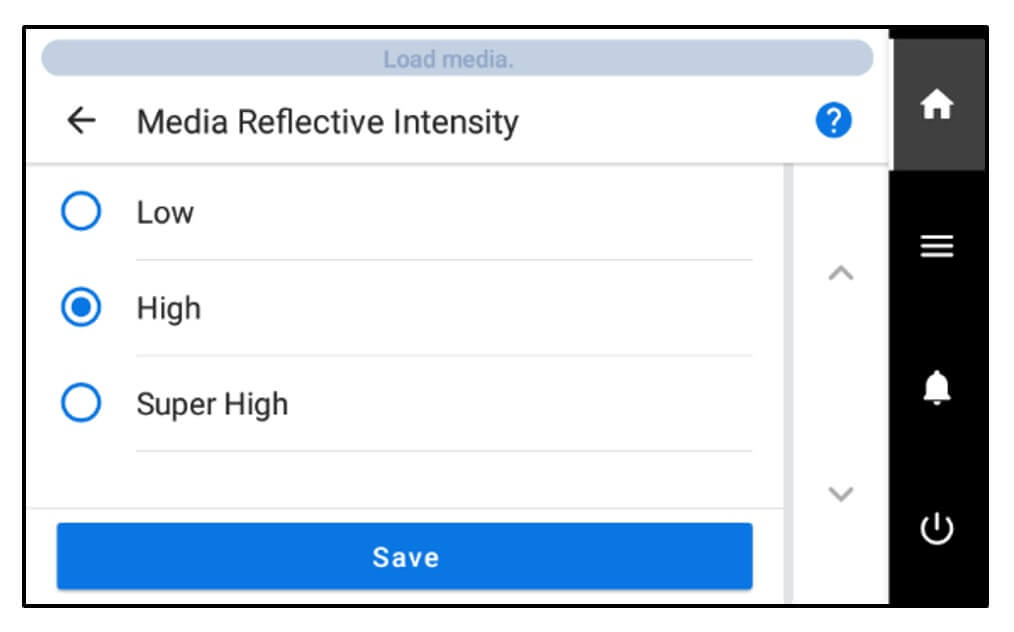

When setting up a new object on the VersaOBJECT MO-240 touch display, you have three options when it comes to RI – “Low,” “High,” and “Super High.”

This doesn’t really tell you much, so you need to know what defines each of these options. The bottom line is that the amount of time required for automated cleaning increases with “High” and “Super High” RI settings.

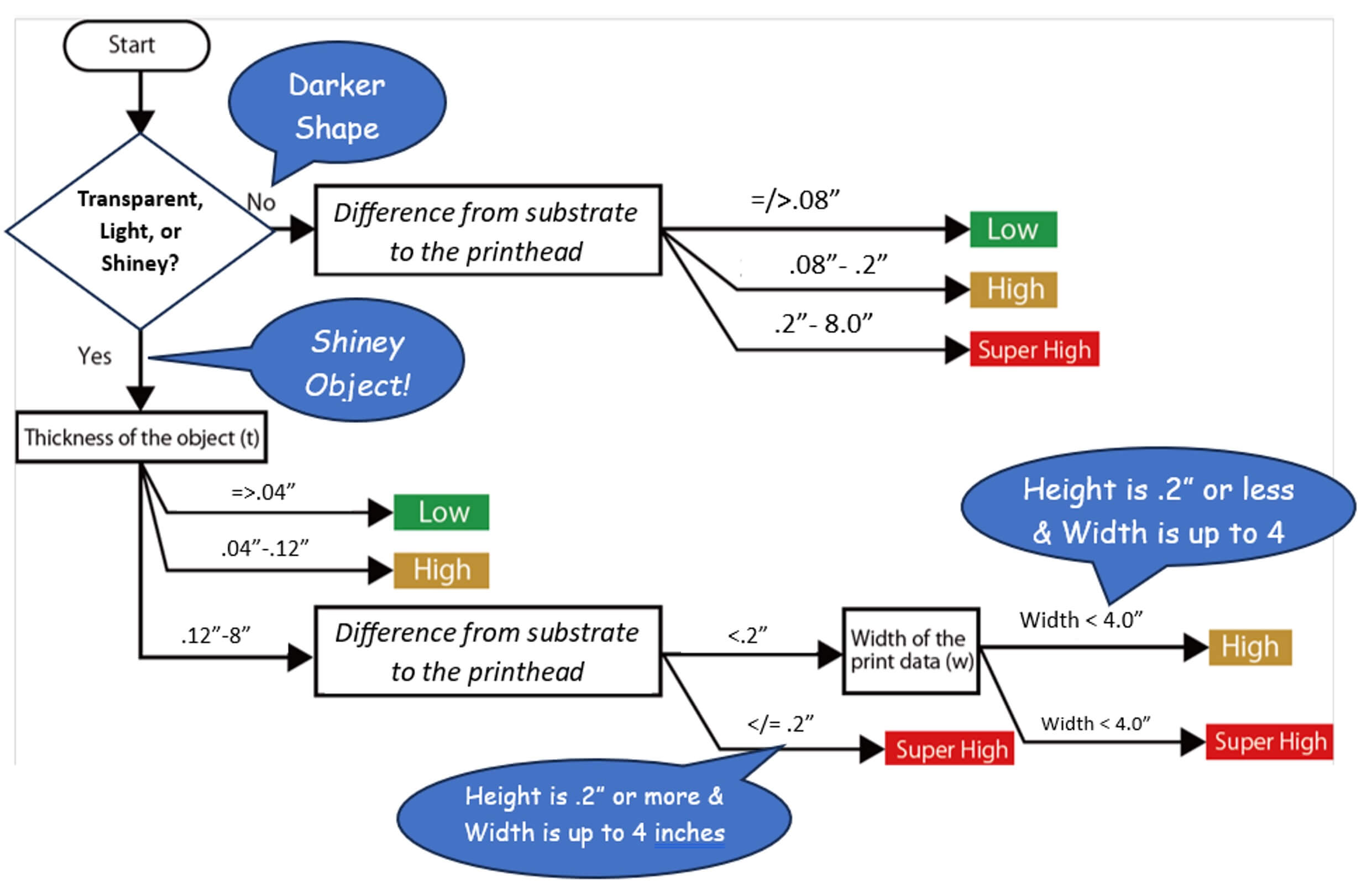

It was surprising to learn that it doesn’t take much to get RI to impact printheads. The two things to pay attention to are size and color. The chart below provides a benchmark of why and when to use different settings for Media Reflective Intensity:

It’s important to realize that the RI cleaning will ultimately result in longer printhead life and increased production. It is the end user’s call to set the level that’s best for his or her business. With this in mind, knowing how and why the MO-240 operates as it does is extremely helpful.