by Lily Hunter, Senior Product Manager - Roland DGA

I have been receiving various questions from customers who are new to the printing/cutting industry and have recently purchased a Roland DG desktop product. The most commonly asked questions that I get from new BN-20 or GS-24 owners are related to the blade and cutter settings.

We have a good Cutter Blade Reference Guide on our product support page for the GS-24, but this useful resource is often overlooked. With that in mind, I’d like to highlight three things from that document. Feel free to share this information with your customers – whether they have a cutter, a print/cut device, or both

- Blade Extension – The tendency is to set the blade in the blade holder with the tip of the blade visible. While this sounds intuitive enough, it’s incorrect. We don’t actually need to see the blade. A colleague of mine described this the best – you should feel the blade, but not see it. Run the blade over a scrap piece of vinyl and see if it cuts it. Our reference guide (page 2) states that the best amount of extension to use as a starting point is half the thickness of a credit card. Next, do a cut test to determine if additional downforce is needed and/or more blade extension is required.

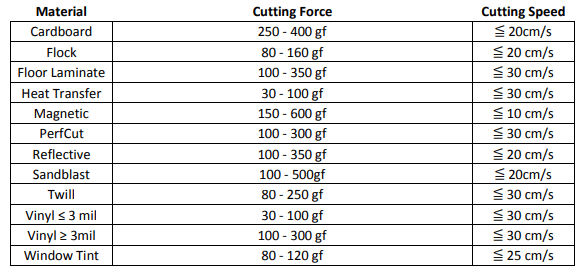

- Cut Force – If you’re doing a CutContour (contour cutting), the media should be cut with enough force/pressure that you do not see cut lines in your liner. Cut force is measured in grams force (gf). For some media, like our HeatSoft™ heat transfer material, too much cut force actually pushes the cut media edges into the liner, resulting in cut media that is difficult to weed. On page 3 of the guide, there are recommended blade settings for different types of media. Below is the chart from that page:

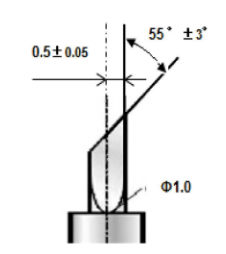

- 45° or 60° Blade? Offset? The angle of the blade design is referenced in degrees. In the illustration to the right, the angle is 55°. The offset – the measurement from the middle of the blade to the edge of the blade – determines the turning radius. In the illustration, the offset is 0.5. Typically, a 45° blade is a multi-purpose blade for most media < 3 mil. A 60° blade is best for thicker media that’s > 3 mil.

Check out the guide for more information. Happy selling and go get those opportunities out there!