PRINTING ON ACRYLIC

Acrylic is a very commonly used material in construction, signage, manufacturing and décor applications. Acrylic printing machines open your business up to so many opportunities in sign and graphics customization. From printing onto acrylic products, to printing onto full acrylic sheets, sign and graphics suppliers need to understand this versatile material and the specific machines that are designed for printing onto acrylic.

A Guide to Acrylic Printing

Acrylic is also known for its popular brand names like, Plexiglas, Lucite, Acrylite and Perspex. The major benefit of printing onto acrylic is that it’s lightweight, impact resistant, and durable. It’s also more adaptable to direct print methods like UV printing when compared to glass that has more of a moisture-repellent silicate surface that’s more challenging to print on.

It’s also more adaptable to direct-print methods (like UV printing) when compared to glass, which has more of moisture-repellent silicate surface that’s more challenging to print on.

|

It’s used in manufacturing, construction, décor and indoor sign applications. |

| It’s used in manufacturing, construction, art, décor and indoor sign applications. |

|

It’s used in manufacturing, construction, and outdoor sign applications. |

|

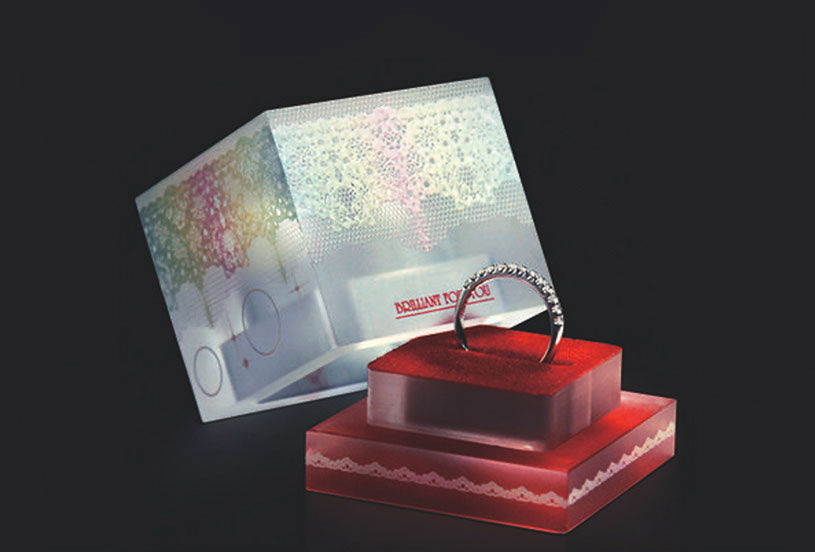

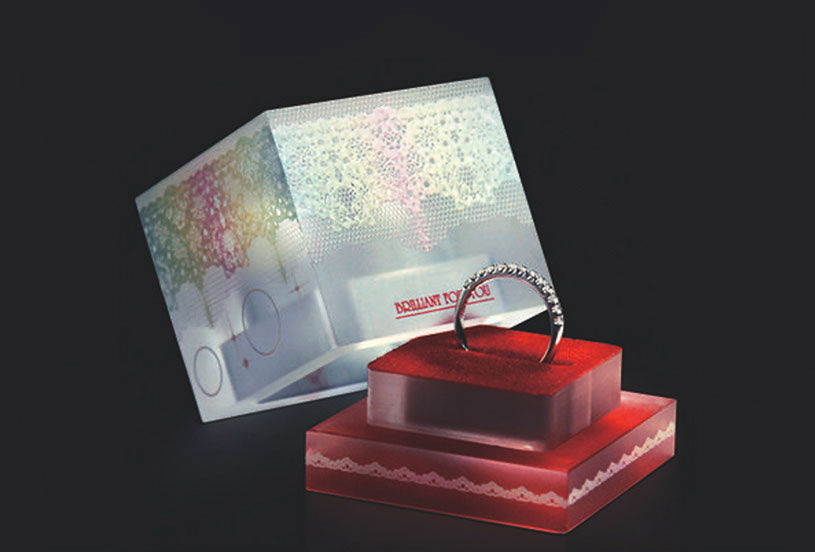

It’s used in manufacturing, construction, packaging, and sign applications. |

Printing on Acrylic Products

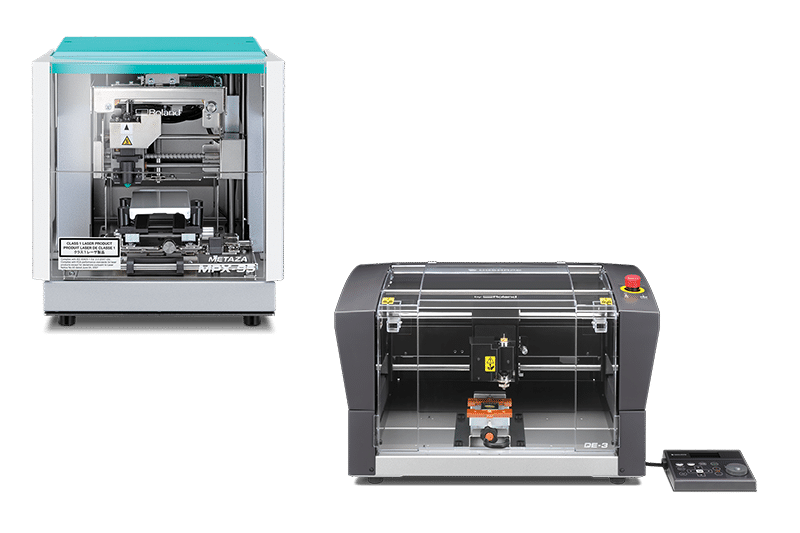

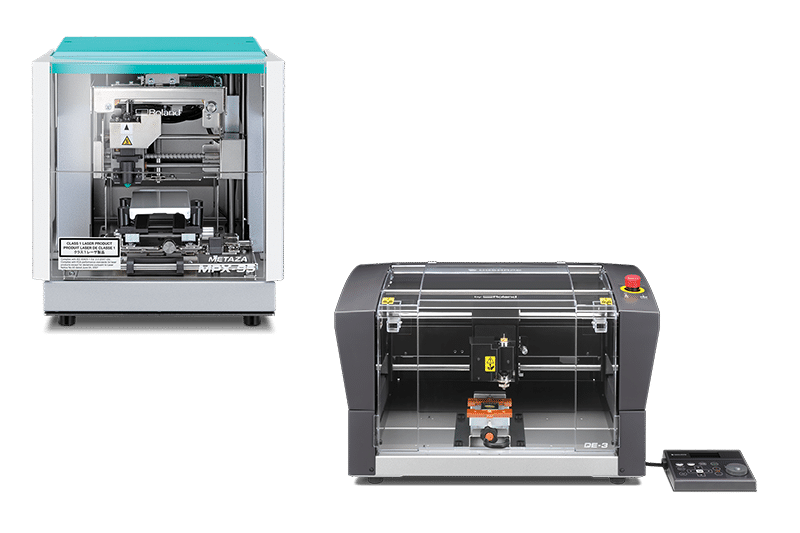

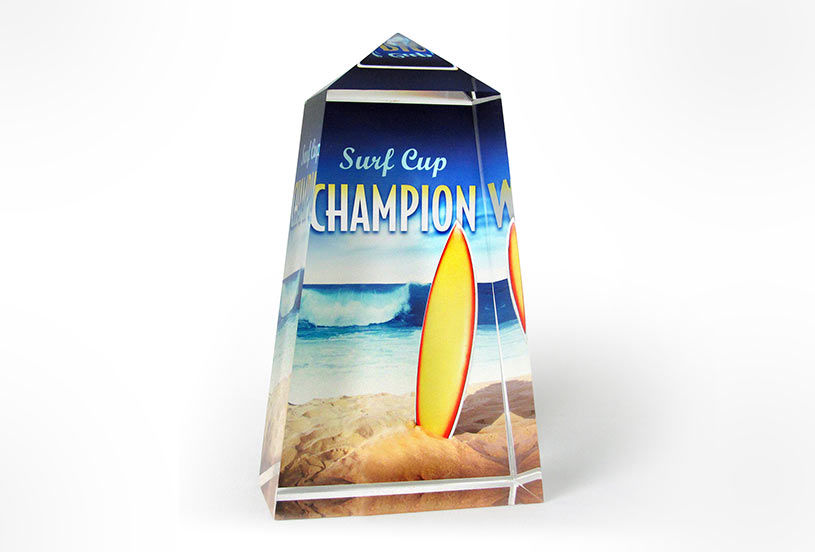

Acrylic is a great substitute for glass, especially when it comes to shields, trophies, and award products. It doesn’t smash like glass or represent a safety risk if it cracks or breaks. Because of its glass-like luminescence, it’s also used for home décor applications items like candle holders, wall plates, lamps, and even larger items like end tables and chairs. Use VersaOBJECT or VersaUV flatbed technology to print directly onto these items, or engrave them with a Roland DG rotary engraving machine.

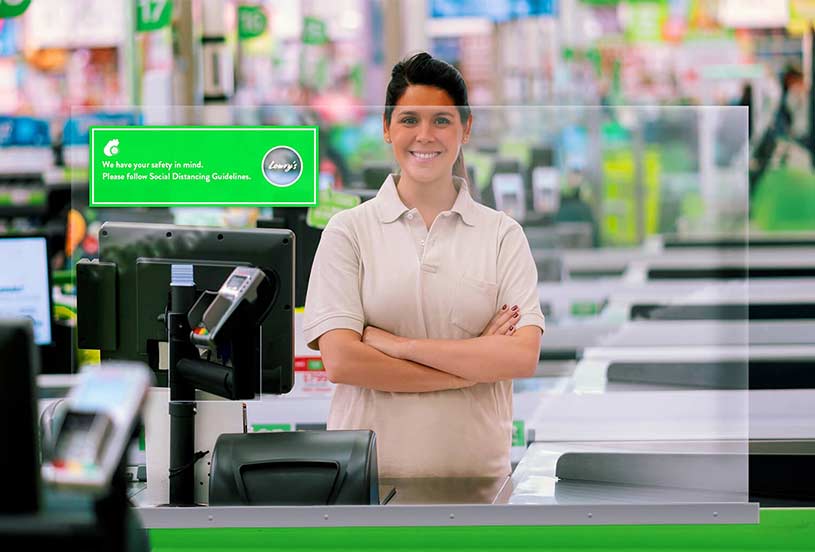

Printing on Acrylic Stands, Signs, and Displays

Acrylic is used to create signs, stands and displays for restaurants, museums, tradeshows, and many other applications. Easy to bend, it lends itself to making products like end caps for store displays or brochure holders for car dealerships. Acrylic is also used extensively in schools, hospitals, and stores. Because it’s durable and see-through, it’s also often used for stylish and sophisticated office signs and door plaques.

Printing onto Acrylic for Prototypes and Packaging

Printing onto Full Sheets of Acrylic for

Sign, Construction, and Promotion

There are multiple ways to create standout panels, sliding doorways, standing graphics and more for tradeshow booths, restaurant interiors, offices, hotels, and other applications. Add graphics by mounting vinyl graphics directly to acrylic media. Or, print directly onto full sheets of acrylic with an EU-1000MF to create signs and graphics for home businesses and interiors quickly and cost-effectively.