En los últimos años, la impresión UV se ha vuelto cada vez más popular, siendo reconocida en la industria de los letreros y gráficos por ser capaz de generar imágenes de alta calidad sobre una gran variedad de sustratos y objetos tridimensionales.

¿Qué es la Impresión UV?

La impresión UV es uno de los más flexibles procesos de impresión directo-a-objeto jamás creados, y sus usos son casi ilimitados. Los beneficios de la impresión UV incluyen:

Producciones rápidas con curado instantáneo de tintas.

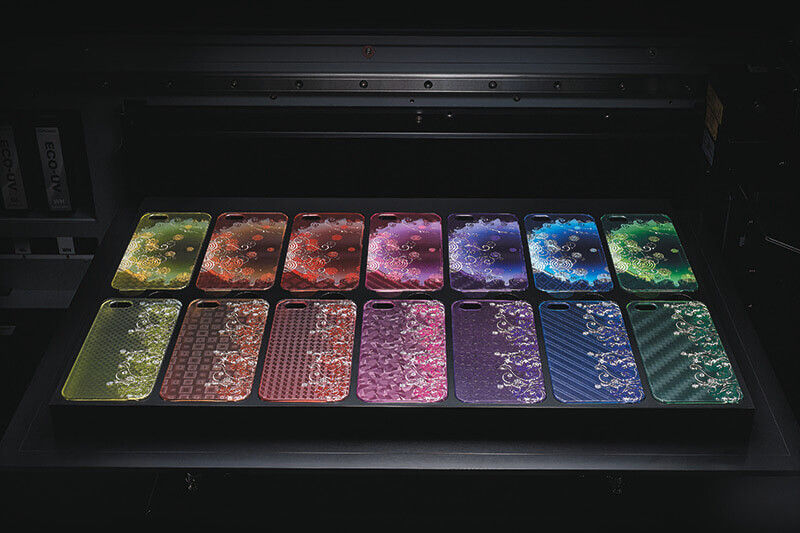

- Habilidad de imprimir directamente sobre una amplia gama de materiales y objetos.

- Habilidad de imprimir efectos especiales texturados y detalles satinados.

- Al usar la tecnología de impresión UV, se puede imprimir diseños personalizados, imágenes, textos e incluso texturas directamente sobre una amplia variedad de materiales y productos.

La impresión digital acelera el proceso de producción gráfica al curar de forma instantánea, usando lámparas UV, tintas UV especialmente formuladas.

Sin embargo, como con cualquier tecnología, existen algunos conceptos erróneos que la rodean.

En este artículo vamos a derrumbar algunos de los más comunes mitos de la impresión UV y aclarar las verdades de esta versátil tecnología.

Las tintas UV V-BOND de Roland DG están formuladas para ser seguras al usarse en entornos médicos y de cuidado infantil.

Mito № 1: la Impresión UV es Dañina para el Medioambiente.

Uno de los más persistentes mitos sobre la impresión UV es que perjudica al medioambiente. Algunos creen que las tintas UV usadas en el proceso de impresión son tóxicas y contribuyen a la contaminación del aire. Sin embargo, esto está bastante lejos de la verdad.

La impresión UV en verdad ofrece varios beneficios al medioambiente:

- Las tintas UV están libres de compuestos orgánicos volátiles (VOC) y no emiten vapores dañinos durante el proceso de curado.

- Las más recientes fórmulas de tintas UV, tales como las de las tintas V-BOND de Roland DG, están especialmente diseñadas para cumplir con las normas de la Ley de Mejora de la Seguridad de Productos de Consumo (CPSIA) y de seguridad para juguetes infantiles.

- Finalmente, debido a que las impresoras UV emplean lámparas UV/LED ecológicamente seguras en el curado, consumen en general menos energía que otros procesos de impresión.

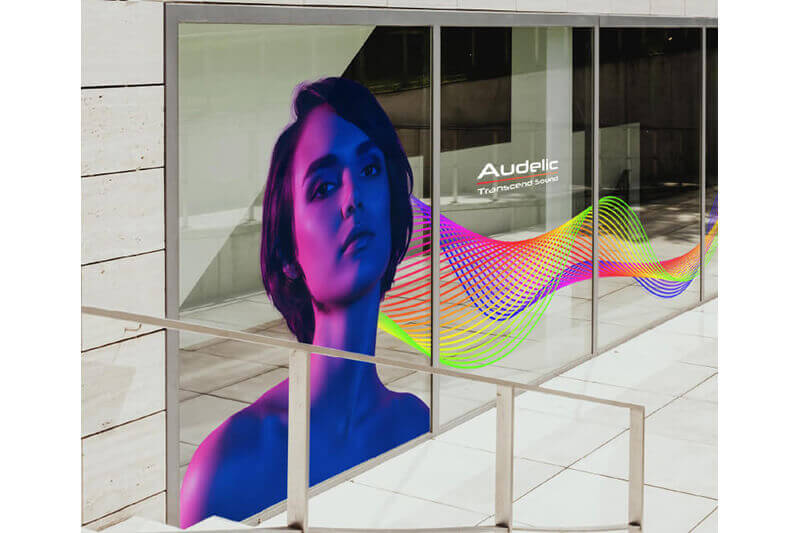

Con una impresora UV usted puede dar rienda suelta a su creatividad en una amplia variedad de sustratos y artículos tridimensionales.

Mito № 2: la Impresión UV Está Limitada a Determinados Materiales.

Otro mito común sobre la impresión UV es que está limitada a materiales específicos, como superficies planas o sustratos rígidos. Este mito puede haberse originado durante la primera era de la impresión UV, cuando esta tecnología era principalmente usada en materiales planos como papel y cartón.

Sin embargo, la impresión UV ha progresado bastante desde entonces. Las impresoras UV modernas son capaces de imprimir sobre una amplia variedad de materiales, incluyendo:

De hecho, debido a su excelente consistencia a través de múltiples sustratos, el perfilado de colores para cada sustrato es reducido considerablemente. Las impresoras UV híbridas de Roland DG ofrecen impresión tanto rollo-a-rollo como de cama plana, una máxima flexibilidad.

La versatilidad de la impresión UV la hace la opción preferida en industrias como las de letreros, envases, productos promocionales, personalización y adaptación y diseño de interiores.

Las tintas UV de Roland DG, de formulación especial, producen impresiones ricas y vibrantes.

Mito № 3: la Impresión UV da como Resultado una Calidad de Imagen Inferior.

Algunos escépticos dicen que las tintas UV son de algún modo “apagadas” y no brindan los mismos niveles de vivacidad cromática y nitidez que los de las tintas tradicionales. Sin embargo, este mito se derrumba bajo escrutinio. La gama de colores de Roland DG para sus tintas EUV5 de Roland DG habilita a los usuarios a lograr los mismos niveles de riqueza y vivacidad cromática que pueden ser alcanzados con sus tintas eco-solventes. Las tintas EUV5, desarrolladas para sacar el máximo provecho de los dispositivos de inyección de tinta VersaUV® de la Serie LEF2, las impresoras de cama plana e híbridas VersaOBJECT® de la Serie CO, y las impresoras UV/ cortadoras TrueVIS de las Series LG y MG, incluyen Rojo y Naranja que expanden la gama cromática y permiten lograr colores antes inalcanzables.

Adicionalmente, todas las tintas UV son curadas de forma instantánea usando luz ultravioleta. Este proceso de curado garantiza que las tintas no se dispersen ni traspasen el sustrato, y da como resultado impresiones vibrantes, nítidas y de alta resolución. Además, la impresión UV permite una colocación precisa de puntos, mejorando la claridad y detalle de las imágenes en general.

Las impresiones giclée hechas con una impresora UV Roland usan capas de tintas que simulan pinceladas.

Mito № 4: la Impresión UV es lenta.

Este mito antes no lo era; de hecho, la impresión UV era más lenta que otras formas de impresión digital. Sin embargo, las impresoras UV de hoy en día han superado este inconveniente. Las impresoras UV/cortadoras profesionales TrueVIS de la Serie LG logran velocidades de impresión tres veces más altas que las de los modelos anteriores. Las LG también imprimen más rápido que las impresoras de la competencia, a la vez logrando la calidad de impresión y confiabilidad asombrosas que los usuarios Roland esperan.

Mito № 5: la Impresión UV es Cara.

Hay una idea falsa bastante divulgada de que la impresión UV es prohibitivamente costosa, haciéndola una opción poco práctica para muchas empresas. Aunque es cierto que las impresoras UV pueden tener un costo inicial más alto que el de otras impresoras tradicionales, permiten gastos de operación significativamente reducidos.

La impresión UV elimina la necesidad de procesos adicionales como laminado o barnizado –a menudo requeridos en métodos tradicionales de impresión–, ahorrando tiempo y dinero en cada gráfico generado. Además, el curado instantáneo de las tintas UV reduce el tiempo de producción e incrementa la productividad en general. Por último, la tecnología UV permite una impresión a pedido, eliminando la necesidad de largos procesos de producción y reduciendo desperdicios.

Las impresoras UV de formato ancho crean gráficos durables para interiores y exteriores.

Mito № 6: las impresiones UV no son buenas para gráficos de vehículos ni para otras aplicaciones de exteriores.

Algunos creen que las impresiones UV no son convenientes para gráficos de vehículos u otras aplicaciones de exteriores. Aquí es importante recordar que ha habido muchos avances tanto en la tecnología de impresoras como en la formulación de tintas UV.

La gran mayoría de aplicaciones de impresión de formato ancho de exteriores están diseñadas para durar tres años o menos. Este periodo coincide con el ciclo de vida útil de las actuales tintas UV que pueden resistir con facilidad la intemperie. De hecho, las tintas UV responden bien con una de las más populares aplicaciones de exteriores: la rotulación de vehículos –especialmente la de los lados de camiones y remolques–. Con su innata elasticidad, las tintas UV pueden soportar cómodamente los efectos de los cambios de temperatura en exteriores, a la vez estirándose sobre los contornos de los paneles de las carrocerías.

El software RIP VersaWorks®, de fácil uso, se incluye con cada impresora UV Roland DG.

Mito № 7: el Software RIP de una Impresora UV es Caro y Complicado.

En el pasado, algunos programas de software RIP para impresoras UV habían sido descritos como costosos y difíciles de usar. Aunque algunos paquetes de software RIP pueden ser caros si se compran por separado, todos los dispositivos de impresión UV de Roland DG incluyen la más reciente versión del software RIP VersaWorks® de la empresa. Roland DG ha creado el software VersaWorks® para que sea extremadamente fácil de usar, incluyendo la tecnología “arrastrar y colocar” y otras herramientas y funciones de manejo simple. Este RIP es también altamente eficiente, permitiendo a los usuarios controlar hasta cuatro dispositivos Roland DG simultáneamente.

Roland DG brinda un continuo soporte para los usuarios de VersaWorks® en todos los aspectos de la impresión, incluyendo embaldosado, anidado, impresión de datos variables, perfilado de colores y colas de impresión, a través de su servicio técnico en línea y en persona, y de su serie de videos en Roland TV.

Conclusión.

Las tintas e impresoras UV de la actualidad han demostrado que muchos mitos circulando sobre estas tecnologías son simplemente eso. Las impresoras UV de Roland DG se han establecido como dispositivos revolucionarios en la industria gráfica. Sus beneficios al medioambiente, versatilidad, rentabilidad, y gráficos de excelente calidad de imagen hacen de la impresión UV la opción preferida de empresas a través de varios sectores.

Como con cualquier tecnología, es importante separar la realidad de la ficción y mantenerse informado acerca de las habilidades y ventajas de la impresión UV. Desmentir estos falsos conceptos comunes le ayudará a tomar una decisión informada sobre si una impresora UV de Roland DG es la adecuada para sus necesidades gráficas.

¿Tiene más preguntas acerca de la impresión UV? Comuníquese con un experto de Roland DGA haciendo “clic” aquí.