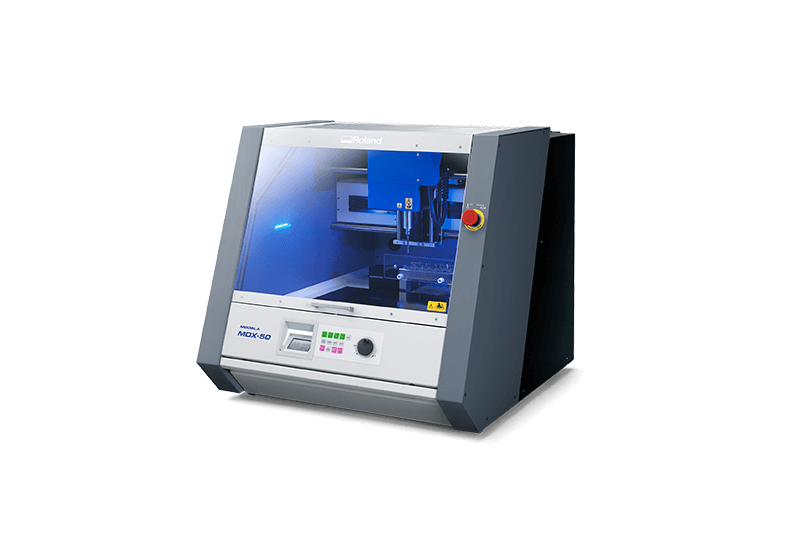

Benchtop Milling Machines

MODELA MDX-50 Benchtop Milling Machine

Automatic 3D milling of parts and prototypes for users of all abilities

- Mill plastic foam, ABS, POM, modeling wax, plywood, hardwood, etc.

- 5-station Automatic Tool Changer for continuous operation

- Expanded machining area 15.8” (X) x 12” (Y) x 5.3” (Z)

- Bundled with user-friendly CAM software

- Optional rotary axis with self-centering headstock and tailstock workpiece clamps